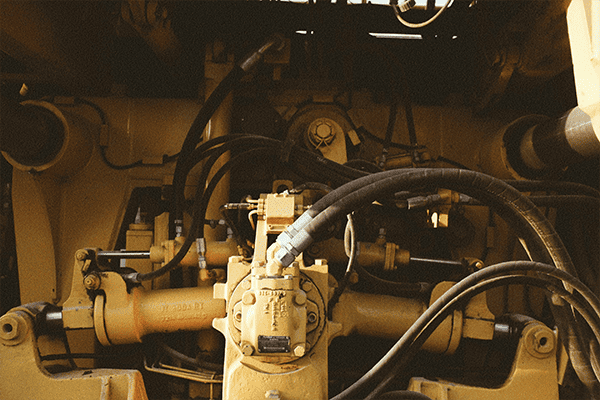

Hydraulic hose over-crimping1 can lead to costly equipment failures. Recognizing the risks is crucial to ensuring safety and performance.

Over-crimping compresses the hose excessively, potentially causing structural damage2 and system inefficiencies. Prevention is key to maintaining performance.

Understand the causes and implications of over-crimping to protect your investment and prolong equipment lifespan.

Can you over crimp a hydraulic hose?

Over-crimping a hydraulic hose occurs when excessive force deforms the hose, reducing flow efficiency and risking failure.

Yes, over-crimping damages the hose structure and may lead to leaks or bursts, compromising system safety.

Why over-crimping is harmful?

Over-crimping can weaken the hose walls or create pinch points that block fluid flow. The damaged section often becomes a failure point under pressure.

| Impact of Over-Crimping | Consequences |

|---|---|

| Restricted flow | Reduced system efficiency |

| Weakened hose structure | Increased risk of failure |

| Pinched fittings | Equipment damage or injury |

Preventing over-crimping ensures reliability and safety, saving money in repairs and downtime.

What causes hydraulic hose failure?

Hydraulic hose failure3 stem from many factors, including over-crimping, poor maintenance, and extreme operating conditions.

Common causes include misalignment, incorrect fittings, and exceeding pressure ratings4

Dive deeper into failure causes

Failures occur when the system operates beyond design limits or maintenance is neglected. Common issues include:

1. Excessive Pressure

Hoses are rated for specific pressures. Exceeding these limits can lead to ruptures.

2. Incorrect Installation

Improper crimping, kinks, or misaligned fittings put unnecessary stress on hoses.

| Failure Cause | Prevention Tips |

|---|---|

| Pressure overload | Use hoses rated for your system pressure |

| Poor maintenance | Regularly inspect and replace components |

| Installation errors | Train operators on proper procedures |

Proper care and usage extend the lifespan of hydraulic hoses, reducing risks.

Which is the most common form of damage to a hose?

Abrasion and external wear5 are among the most frequent forms of hose damage in hydraulic systems.

Abrasion weakens the hose, making it prone to leaks and failures over time.

Dive deeper into abrasion and wear

Hydraulic hoses are often exposed to harsh environments. Protective covers or sleeves6 help reduce external damage.

Key Factors in Abrasion Damage

- Contact with sharp surfaces: Repeated rubbing erodes the hose material.

- Improper routing: Poor placement increases wear from movement or vibration.

| Type of Damage | Prevention Methods |

|---|---|

| Abrasion | Use protective sleeves or covers |

| Internal erosion | Avoid contaminants in hydraulic fluid |

How to properly crimp a hydraulic hose fitting?

Crimping a hydraulic hose requires precision and adherence to manufacturer specifications.

Use calibrated equipment and follow step-by-step guidelines for accurate crimping.

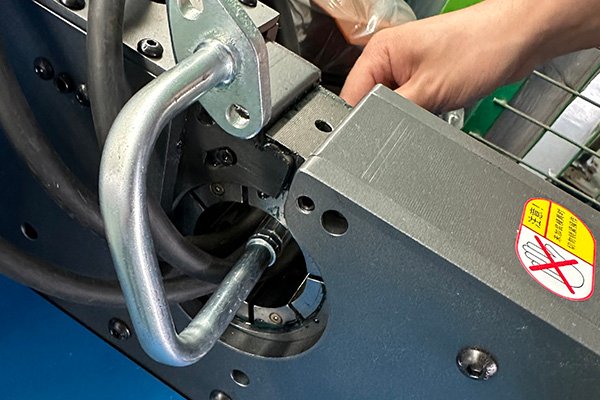

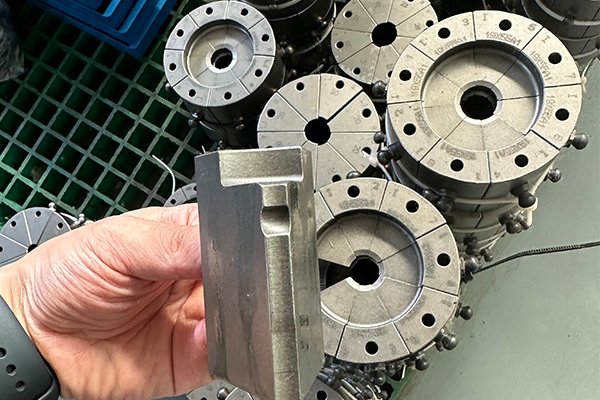

Steps to proper crimping

-

Measure the Hose

Cut to the required length using a hose-cutting machine. -

Select the Right Die

Match the die size to the hose and fitting. -

Position the Fitting

Insert the fitting correctly into the hose. -

Crimp Securely

Use a crimping machine to compress the fitting evenly. -

Inspect the Crimp

Check for deformities or uneven compression.

| Crimping Step | Best Practices |

|---|---|

| Measuring | Ensure precise cuts for tight seals |

| Selecting dies | Use manufacturer-recommended tools |

| Final inspection | Verify crimp quality before use |

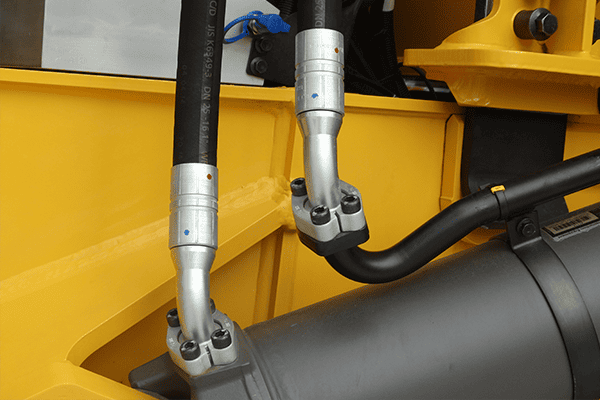

Can you over tighten hydraulic fittings?

Over-tightening hydraulic fittings7 can cause thread damage or compromise seals, leading to leaks.

Yes, excessive tightening can deform threads or fittings, reducing system reliability.

Effects of over-tightening

-

Thread Damage

Over-tightening can strip or deform threads, causing permanent damage. -

Seal Compromise

Excess pressure can crush O-rings or sealing surfaces.

| Over-Tightening Impact | Consequences |

|---|---|

| Thread stripping | Difficulty maintaining seals |

| Seal damage | Increased risk of leaks |

Use a torque wrench to tighten fittings to the recommended specifications.

Can you over tighten hose clamps?

Hose clamps should secure hoses without damaging the underlying material.

Yes, over-tightening clamps can crush the hose and cause leaks.

Dive deeper into proper tightening

Hose clamps need careful adjustment to avoid uneven compression. Key tips include:

- Check Material Compatibility: Match the clamp type to the hose material.

- Apply Even Pressure: Avoid overtightening to prevent material deformation.

| Tightening Tips | Benefits |

|---|---|

| Moderate pressure | Prevents leaks without damage |

| Correct placement | Improves hose clamp effectiveness |

Conclusion

Understanding the risks of over-crimping, over-tightening, and improper maintenance ensures safer, more efficient hydraulic systems. Focus on precision and prevention to extend equipment life.

-

Learn the causes and effects of over-crimping to avoid costly failures and extend equipment life. ↩

-

Understand how over-crimping impacts hose integrity and performance in hydraulic systems. ↩

-

Identify common causes of hydraulic hose failure and effective prevention strategies. ↩

-

Learn about pressure ratings for hydraulic hoses and how they prevent failure. ↩

-

Explore the impact of abrasion and wear on hydraulic hoses and how to protect them. ↩

-

Understand the importance of protective sleeves in extending the life of hydraulic hoses. ↩

-

Discover how over-tightening hydraulic fittings can reduce system performance and cause leaks. ↩

3 Responses