Struggling to understand the difference between tubes, pipes, and hoses1? You're not alone; these terms often create confusion.

Tubes, pipes, and hoses vary in application, material, and measurement standards, catering to specific needs in fluid and gas transport.

Discover the key distinctions between these components and how they fit into various industries. Let's clarify the confusion.

How does a pipe differ from a tube?

Pipes and tubes might look similar, but their purpose, measurement, and structure are not the same.

Pipes2 are measured by internal diameter for fluid flow, while tubes3 focus on external diameter for structural precision.

Dive Deeper: The Purpose and Key Differences

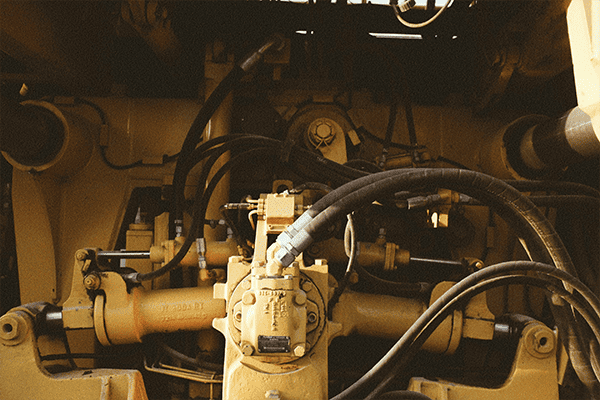

Pipes are generally used for transporting fluids or gases over long distances. They are measured by their internal diameter (ID) to ensure proper flow rates. Pipes are classified by schedules that indicate wall thickness.

Tubes, on the other hand, are often used for structural applications where precision and strength are required. They are measured by their external diameter (OD), ensuring consistency in fitment and assembly. Tubes are more standardized in terms of shape and size.

| Feature | Pipe | Tube |

|---|---|---|

| Measurement | Internal Diameter (ID) | External Diameter (OD) |

| Applications | Fluid and gas transport | Structural or precision |

| Shape | Circular | Circular, square, etc. |

Both are essential in industries, but choosing the right one depends on the project requirements.

What do Americans call a hose pipe?

The term "hose pipe4" might sound unusual to some. Is it a hose or a pipe?

Americans typically refer to a "hose pipe" as just a "hose5," used for flexible water transport.

Dive Deeper: Regional Terminology Explained

In the U.S., "hose pipe" is rarely used. Instead, "hose" is the preferred term. This flexible tube is commonly used in gardens, automotive systems, and other applications requiring mobility.

British English, however, often combines the words "hose" and "pipe" into "hose pipe," emphasizing its utility in water transport. While the terms may differ, their functionality remains consistent across regions.

Is a hose a pipe?

A hose might share similarities with a pipe, but are they the same?

No, a hose is not a pipe. Hoses are flexible, while pipes are rigid and fixed in place.

Dive Deeper: Flexibility vs. Rigidity

Hoses are designed for mobility and flexibility. They are commonly made of rubber, plastic, or composite materials to allow bending and movement. This makes hoses ideal for applications like watering plants, connecting machinery, or transferring fluids in dynamic environments.

Pipes, in contrast, are typically rigid and made of metal, PVC, or other sturdy materials. Their purpose is to establish permanent or semi-permanent systems for fluid and gas transfer, such as plumbing or industrial pipelines.

| Aspect | Hose | Pipe |

|---|---|---|

| Flexibility | Flexible and portable | Rigid and fixed |

| Materials | Rubber, plastic, composite | Metal, PVC |

| Use Case | Temporary setups | Permanent systems |

Understanding this distinction helps in selecting the right component for the task.

What is the difference between an air tube and an air hose?

Air tubes6 and air hoses7 both transport air, but their design and usage vary.

Air tubes are rigid and precise, while air hoses are flexible and durable for mobile applications.

Dive Deeper: Design and Functionality

Air tubes are typically used in systems requiring fixed routing and high precision, such as pneumatic equipment in industrial automation. They maintain a constant shape and are made from materials like nylon or polyurethane.

Air hoses, on the other hand, are designed for flexibility. They are used in dynamic applications like powering air tools or inflating tires. Their durable construction allows them to handle frequent movement and environmental stresses.

| Attribute | Air Tube | Air Hose |

|---|---|---|

| Flexibility | Rigid | Flexible |

| Material | Nylon, polyurethane | Rubber, reinforced plastic |

| Application | Stationary systems | Mobile systems |

Choose the right one based on whether precision or mobility is your priority.

What is the difference between a tube and a hose?

Tubes and hoses might seem interchangeable, but their functions and structures differ.

Tubes are rigid and precise; hoses are flexible and adaptable to dynamic tasks.

Dive Deeper: Applications and Benefits

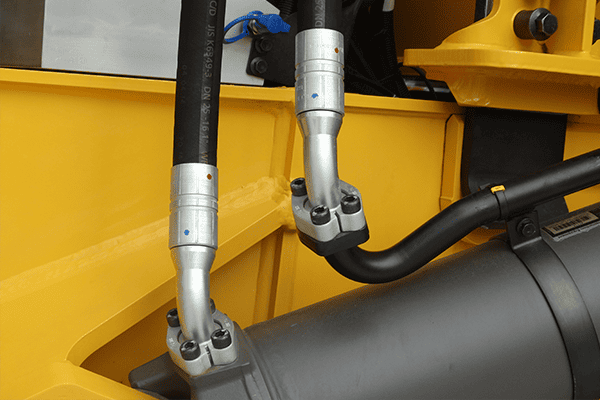

Tubes are essential in environments requiring precision and rigidity. They are often used in hydraulic or structural applications where strength and uniformity matter. Materials like stainless steel or hard plastics ensure durability and consistent performance.

Hoses excel in applications where flexibility and mobility are critical. They are used in automotive systems, construction, and irrigation. Their adaptability makes them suitable for a range of environments.

| Feature | Tube | Hose |

|---|---|---|

| Rigidity | Rigid | Flexible |

| Material | Metal, hard plastic | Rubber, soft plastic |

| Use Cases | Hydraulic systems | Mobile fluid transport |

Knowing the difference ensures you choose the correct option for your needs.

What is the purpose of the air tube?

Air tubes are a common component in many systems, but what are they for?

Air tubes deliver pressurized air in fixed, precise pneumatic setups.

Dive Deeper: Role and Importance

Air tubes are designed to transfer pressurized air with minimal resistance and leakage. They are integral to systems like HVAC (heating, ventilation, and air conditioning), pneumatic controls, and industrial automation. Their rigid structure ensures accurate delivery and long-term reliability.

For example, in a factory setting, air tubes connect compressors to machinery, ensuring efficient operation. These tubes are made from materials like PVC, polyurethane, or nylon to withstand pressure and temperature variations.

| Attribute | Description |

|---|---|

| Material | PVC, polyurethane, nylon |

| Application | Pneumatic systems, HVAC |

| Benefit | Precision and reliability in air delivery |

The air tube's purpose highlights its critical role in various industrial and commercial systems.

Conclusion

Tubes, pipes, and hoses serve unique roles across industries. Knowing their differences ensures efficient and proper usage in any application.

-

Explains their varying roles, materials, and measurement standards. ↩

-

Understand pipe measurement standards and their industrial applications. ↩

-

Details on why tubes are vital for precise applications. ↩

-

Clarifies regional naming differences for better communication. ↩

-

Provides insights on hose advantages for mobile applications. ↩

-

Explores air tube applications and material choices. ↩

-

Learn about air hoses' benefits for mobile systems. ↩