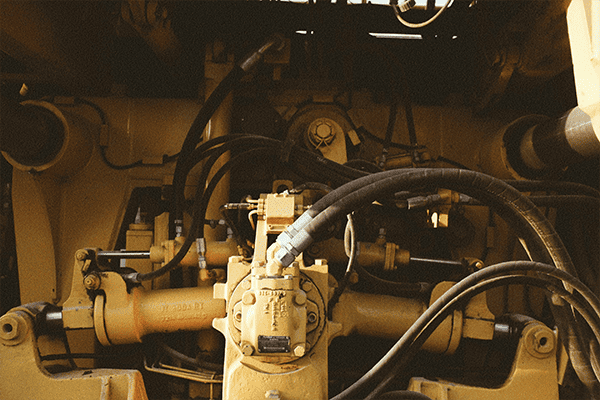

Choosing the right hydraulic hose is crucial for ensuring the safety, reliability, and efficiency of your hydraulic system. With so many options available, it can be difficult to know where to start.

To select the right hydraulic hose, you must consider factors like pressure rating, material compatibility, size1, and environmental conditions.

Transition paragraph: Let’s explore the key factors that will help you make the best choice when selecting a hydraulic hose for your system.

How to choose the right hydraulic hose?

Choosing the right hydraulic hose requires balancing several key factors, including pressure requirements2, fluid compatibility, size1, and temperature range.

To ensure you select the appropriate hose, understand the specific needs of your hydraulic system and the environment it operates in.

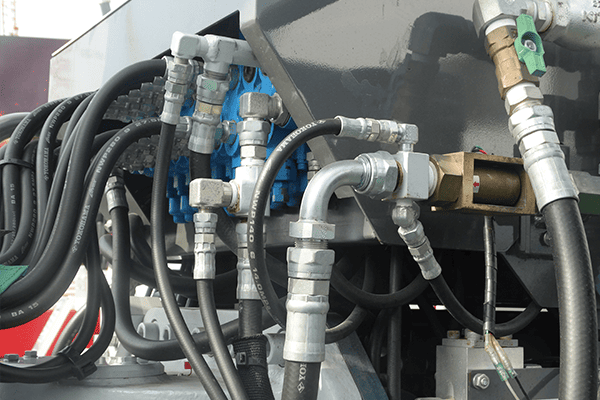

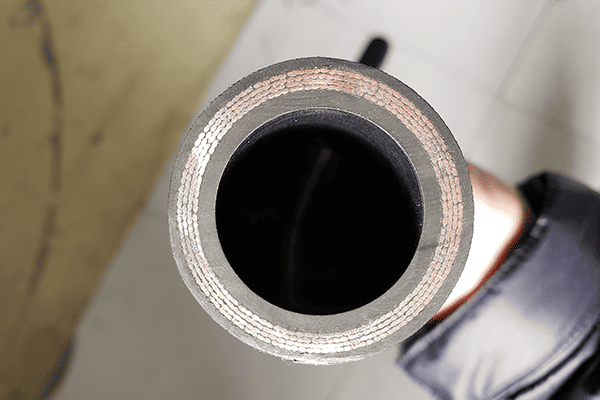

The first step in selecting a hydraulic hose is to determine the pressure rating3 your system needs. Choose a hose that can handle the maximum pressure of the hydraulic system, along with a safety margin. Next, consider the fluid compatibility4; different hoses are designed to work with specific types of hydraulic fluids, such as petroleum-based oils, water-based fluids, or synthetic fluids. The hose material must be resistant to the chemicals, heat, and weather conditions that the hose will encounter. Finally, take into account the size1 and bend radius5 of the hose to ensure it fits your system layout without causing strain or blockages.

Factors to Consider When Choosing a Hydraulic Hose

| Factor | What to Consider |

|---|---|

| Pressure Rating | Ensure the hose can handle maximum operating pressure. |

| Fluid Compatibility | Select a hose that is compatible with the fluid used in your system. |

| Material | Consider the chemical resistance, temperature, and weather conditions. |

| Size & Bend Radius | Make sure the hose fits properly and can bend without stressing. |

Matching these factors to your system’s needs ensures optimal performance.

Which hose is better, 3/4 or 5/8"?

Choosing between a 3/4" and 5/8" hose depends on your specific system requirements, including flow rate, pressure, and space constraints.

The better hose size1 depends on the application and the demands of your hydraulic system.

The 3/4" hose typically has a higher flow capacity than the 5/8" hose due to its larger internal diameter. If your system requires a higher flow of hydraulic fluid, the 3/4" hose may be the better choice. However, the larger hose size1 may be less flexible and take up more space, so consider how it will fit within your system’s layout. On the other hand, a 5/8" hose might be better for smaller systems that don’t need as much fluid flow or for applications with tight space constraints. Always ensure that the hose size1 matches the required flow rate6 to avoid issues like pressure drops or inefficient operation.

Choosing the Right Hose Size

| Hose Size | Internal Diameter | Best Use |

|---|---|---|

| 3/4" | Larger, higher flow | Systems requiring higher fluid flow or longer distances |

| 5/8" | Smaller, lower flow | Systems with tight space or lower fluid flow requirements |

Your system’s flow requirements and space limitations should guide your decision.

What is the most important factor in selecting a hydraulic line?

The most important factor in selecting a hydraulic hose is the pressure rating3. It’s essential to choose a hose that can handle the maximum operating pressure of your system with a proper safety margin.

Pressure capacity is critical for preventing hose bursts and ensuring safe, efficient operation.

The pressure rating3 is determined by the maximum amount of internal pressure a hose can safely withstand. If a hose is rated for a lower pressure than required by your system, it could burst or fail during operation, causing serious damage. Always select a hose with a pressure rating3 higher than the maximum working pressure of your hydraulic system. Additionally, ensure the hose’s burst pressure7 is significantly higher than the operating pressure for added safety. Hydraulic hoses are typically rated by their working pressure, burst pressure7, and impulse life, so it's important to match these ratings to your application.

Key Pressure Factors for Hydraulic Hoses

| Factor | Importance |

|---|---|

| Working Pressure | Should meet or exceed your system’s maximum pressure. |

| Burst Pressure | Hose must withstand higher pressures than the operating system pressure. |

| Impulse Life | The hose’s ability to handle repeated pressure cycles. |

A proper pressure rating3 ensures that the hose can handle your system’s demands.

Do I need a 50 ft or 100 ft hose?

Whether you need a 50 ft or 100 ft hydraulic hose depends on your system’s layout, distance requirements8, and hose flexibility9.

Choosing the right hose length10 is critical for minimizing friction losses and ensuring the hose fits your system’s reach.

The primary consideration when choosing hose length10 is the distance between components in your hydraulic system. A hose that is too long can result in energy loss due to friction, reducing efficiency and flow rate6. On the other hand, a hose that is too short can lead to strain on the system, restricting movement or creating stress points. Choose a length that allows for proper routing without excess slack. If flexibility and space are concerns, you may want to opt for a shorter hose, while longer hoses can provide more flexibility for movement between system components.

Hose Length Considerations

| Hose Length | Best Use |

|---|---|

| 50 ft | Ideal for systems with shorter distances between components. |

| 100 ft | Better for systems that require more flexibility or longer reach. |

Ensure the hose length10 matches the layout of your hydraulic system for optimal performance.

What does JIC stand for in hydraulic fittings?

JIC stands for Joint Industry Council. It refers to a standardized fitting used in hydraulic systems, particularly in the United States.

JIC fittings are designed to provide a leak-proof seal with a 37-degree flare.

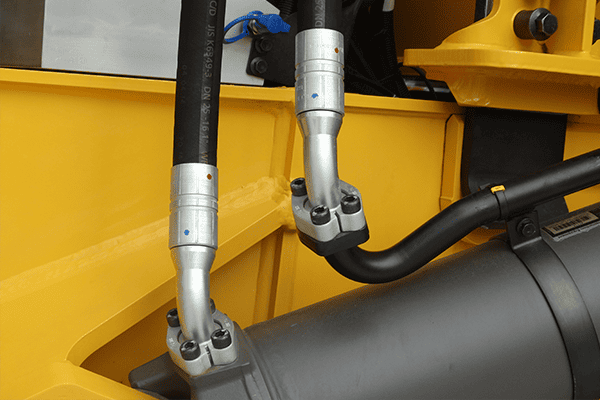

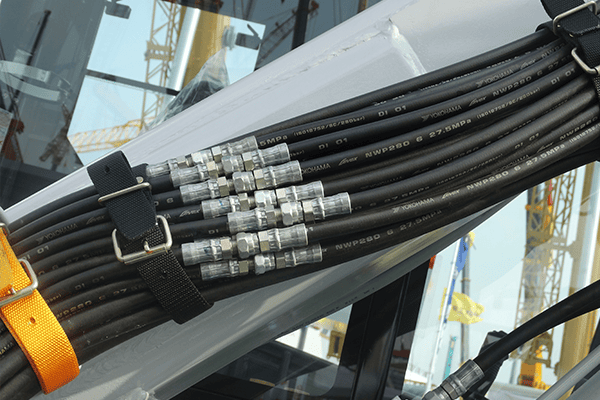

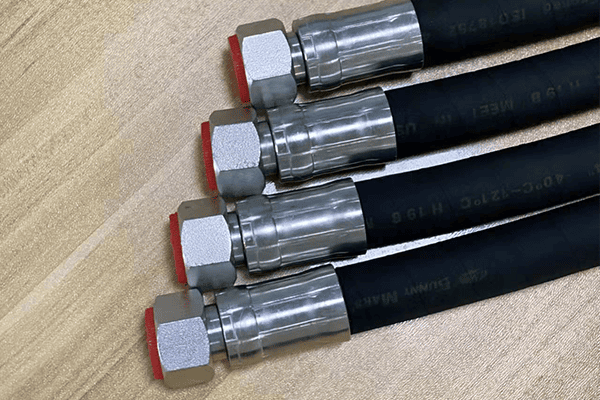

JIC fittings11 have a 37-degree flare12 and are widely used because they offer a strong, reliable seal in hydraulic systems. These fittings are often preferred in high-pressure systems, as the flare creates a tight seal between the hose and the fitting. It’s essential to ensure that the hose and fitting are compatible in terms of size1 and thread type, as using mismatched components can cause leaks and system failure. JIC fittings11 are common in applications like agriculture, construction, and heavy machinery.

JIC Fittings Overview

| Feature | Description |

|---|---|

| Flare Angle | 37-degree flare12 for leak-proof connection |

| Compatibility | Common in high-pressure hydraulic systems |

| Common Use | Agriculture, construction, and heavy machinery |

JIC fittings11 are a reliable choice for a variety of hydraulic systems.

How to know which hose to buy?

To choose the right hydraulic hose, assess your system’s pressure requirements2, fluid type, hose size1, and environmental conditions13.

Matching these specifications ensures you select a hose that performs well and lasts longer.

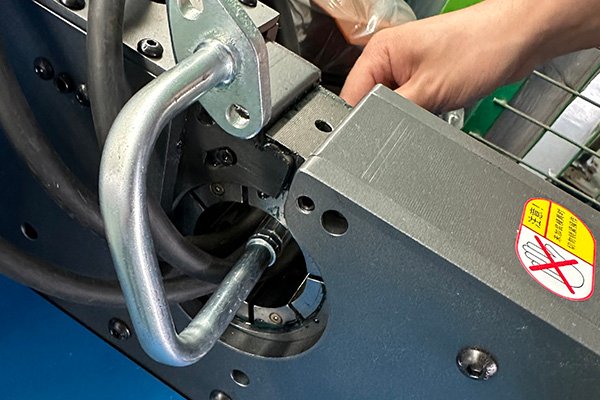

Start by checking the pressure rating3 for your hydraulic system to ensure you select a hose that can withstand maximum working pressure with a suitable safety margin. Next, confirm that the hose material14 is compatible with the type of fluid in your system, whether that’s oil, water-based fluids, or synthetic hydraulic fluids. The hose size1 must align with your system’s flow rate6 and the space available for installation15. Finally, take environmental factors into account—whether the hose will be exposed to heat, UV light, abrasion, or chemicals, and choose materials that can withstand these conditions.

Steps to Choosing the Right Hose

| Step | Action |

|---|---|

| Check Pressure | Ensure the hose can handle system pressure. |

| Assess Fluid Type | Choose a hose compatible with your fluid type. |

| Determine Size | Ensure the hose fits your system’s size1 and flow. |

| Consider Environment | Account for factors like heat, chemicals, or abrasion. |

By following these steps, you can confidently select the right hydraulic hose for your system.

Conclusion

Choosing the right hydraulic hose involves understanding your system’s pressure, fluid compatibility4, size1, and environmental conditions13. By selecting hoses based on these factors, you ensure long-term system reliability16 and safety.

-

Selecting the correct hose size is vital for optimal flow and preventing pressure drops in hydraulic systems. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Evaluating pressure requirements is key to selecting hoses that can safely handle your system's demands. ↩ ↩

-

Understanding pressure ratings is crucial for selecting hoses that ensure safety and efficiency in hydraulic systems. ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring fluid compatibility helps prevent leaks and failures by ensuring the hose material matches the hydraulic fluid used. ↩ ↩

-

Understanding bend radius ensures hoses can be routed without stress, preventing damage and maintaining performance. ↩

-

Understanding flow rate is essential for choosing hoses that meet the demands of your hydraulic system. ↩ ↩ ↩

-

Burst pressure indicates the maximum pressure a hose can withstand, crucial for safety and reliability. ↩ ↩

-

Evaluating distance helps in selecting hose lengths that minimize friction losses and ensure efficient operation. ↩

-

Flexibility allows for better routing and movement, reducing strain on the hydraulic system. ↩

-

Choosing the right hose length minimizes friction losses and ensures proper routing in hydraulic systems. ↩ ↩ ↩

-

JIC fittings provide reliable, leak-proof connections, making them a preferred choice in high-pressure applications. ↩ ↩ ↩

-

Understanding the 37-degree flare helps ensure compatibility and secure connections in hydraulic systems. ↩ ↩

-

Considering environmental factors ensures hoses can withstand conditions like heat, UV light, and chemicals. ↩ ↩

-

Different materials offer varying resistance to chemicals and temperatures, making it essential to choose the right one for your application. ↩

-

Following best practices during installation ensures optimal performance and longevity of hydraulic hoses. ↩

-

Proper hose selection directly affects the reliability and safety of hydraulic systems, preventing failures. ↩