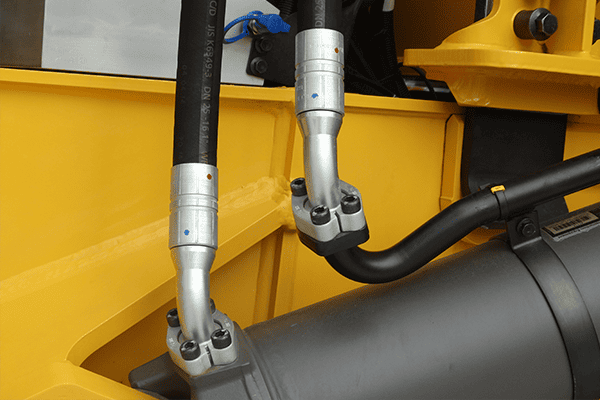

A broken hydraulic hose1 can be a significant issue in any hydraulic system, causing leaks, pressure loss, and potential system failure. While replacing the hose is often the best solution, there are some temporary repair methods for emergency situations2.

Fixing a hydraulic hose1 requires understanding the type of damage and knowing the correct repair methods3 to restore functionality.

Transition paragraph: Let’s explore the ways to repair a broken hydraulic hose1 and the tools and techniques needed to get your system running again.

Can a hydraulic hose1 be repaired?

Yes, a hydraulic hose1 can be repaired, but it depends on the type of damage. Minor damage such as small cuts or nicks may be repairable, while more severe issues, like hose bursts or significant wear, usually require full replacement.

Proper repair methods3 can temporarily fix a hose, but replacement is often the most reliable long-term solution.

If the damage is minor—like a small cut in the outer layer of the hose—it may be possible to use a hose repair kit4 that includes clamps or a specialized hose sleeve. These kits can be effective in the short term to stop fluid leakage and prevent further damage. However, if the hose has been exposed to high pressure and suffers significant internal damage, repairing the hose is generally not recommended. Always assess the damage thoroughly to determine whether a repair or replacement is the best solution. For critical applications, it’s always safer to replace the hose entirely.

When to Repair vs. Replace

| Type of Damage | Repair Option | Recommended Solution |

|---|---|---|

| Small Cuts/Nicks | Hose repair clamp or sleeve | Temporary fix, full replacement recommended soon. |

| Severe Damage | Impossible to repair | Full replacement is required. |

| Wear and Tear | Hose repair kit or external wrapping | Replace to avoid future failures. |

If you're uncertain about the extent of the damage, it's best to consult with an expert.

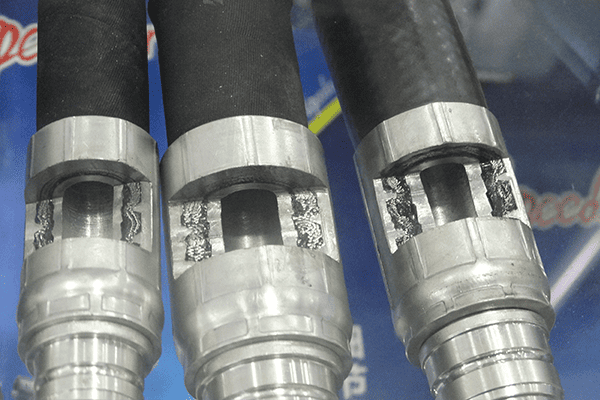

Is it possible to splice a hydraulic hose1?

Technically, it is possible to splice a hydraulic hose1, but it is not recommended for high-pressure applications. Splicing involves cutting the hose and inserting a fitting to join the two ends.

Splicing is a temporary fix and is not suitable for most hydraulic systems, especially those operating at high pressures.

While splicing may seem like a quick solution, it compromises the integrity of the hose and weakens the overall hydraulic system. Splicing creates additional joints that could become failure points under pressure. It’s also difficult to achieve a fully leak-proof seal when splicing hydraulic hose1s, which can lead to dangerous leaks. If splicing is absolutely necessary, use high-quality fittings and ensure the hose ends are securely clamped. However, as a general rule, splicing should only be considered a temporary measure until a replacement hose can be installed.

Risks of Splicing a Hydraulic Hose

| Risk | Impact |

|---|---|

| Pressure Loss | Spliced hoses can’t handle high pressure effectively. |

| Leakage | Imperfect seals lead to leaks, reducing system efficiency. |

| Reduced Hose Strength | Spliced sections create weak points in the hose. |

Splicing is not an ideal solution for safety-critical applications, so replacement is usually the best route.

Can you fix a hydraulic hose1 with tape?

While you can use tape to temporarily seal a hydraulic hose1, it is not a reliable or permanent solution.

Tape may work as a short-term fix in emergency situations2, but it won’t withstand high pressure or long-term use.

In an emergency, wrapping a hydraulic hose1 with heavy-duty tape (such as duct tape or electrical tape) can reduce the leakage5 temporarily. However, tape is not designed to handle the high pressures hydraulic hose1s operate under, and it will fail quickly under these conditions. Even high-strength tapes like Teflon or silicone tape6s are not a permanent fix and can lead to further system failures. It is crucial to replace the hose as soon as possible, especially if the hose is under constant pressure.

Tape vs. Proper Hose Repair

| Method | Pros | Cons |

|---|---|---|

| Tape | Quick, temporary fix | Won’t hold under pressure, not durable. |

| Proper Hose Repair | Longer-lasting, pressure-tested fix7 | Requires proper equipment and expertise. |

Tape should only be considered for temporary use and not as a long-term solution.

Does O'Reilly fix hydraulic hose1s?

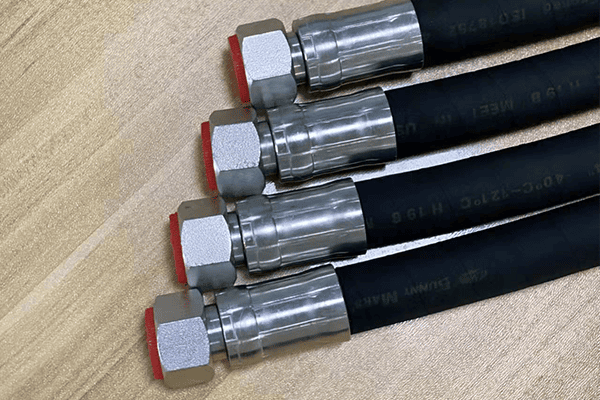

O'Reilly Auto Parts8 does offer hydraulic hose1 repair kits and may assist with basic repairs, such as cutting hose to length or fitting couplings. However, they do not typically offer full hydraulic hose1 repairs in-store.

For comprehensive repairs, you may need to visit a specialized hydraulic service provider9.

While O'Reilly Auto Parts can help with purchasing hydraulic hose1s and related fittings, they generally do not offer full repair services for high-pressure hydraulic hose1s. They can help with basic tasks like hose cutting, adding fittings, or assembling hoses, but for more complex repairs, you will likely need to consult with a hydraulic hose1 repair service or visit a local hydraulics specialist. Always ensure you choose a reputable service provider with the necessary tools and expertise for proper hydraulic hose1 repairs.

Services Offered by O'Reilly

| Service | Available at O'Reilly? |

|---|---|

| Hydraulic Hose Assembly | Yes, with correct fittings and lengths. |

| Hydraulic Hose Repair | Not typically offered in-store. |

| Custom Hydraulic Hose Cutting | Yes, hose cutting and fitting assembly available. |

For high-pressure repairs, it’s best to contact a specialist.

What is the best tape for hydraulic hose1?

The best tape for hydraulic hose1 repair in an emergency is silicone tape. This type of tape is strong, heat-resistant, and can withstand moderate pressures, making it a better option than standard duct tape.

However, silicone tape6 is still a temporary fix and should not be relied upon for long-term repairs.

Silicone tape is a self-adhesive, non-adhesive tape that wraps tightly around the hose and fuses to itself under tension, creating a seal. It's more durable than duct tape and provides some resistance to heat and pressure. However, silicone tape6 is not designed for the high pressure seen in most hydraulic systems. It can be a good choice for emergency situations2, but it should be followed by a proper hose replacement. Always check that the tape is rated for the pressures your system operates under to avoid failure.

Best Tapes for Hydraulic Hose

| Tape Type | Features | Best Use |

|---|---|---|

| Silicone Tape | Heat-resistant, self-bonding, moderate pressure | Short-term emergency fix, not for high pressure. |

| Duct Tape | Quick and inexpensive, but weak under pressure | Emergency use, low-pressure applications. |

| Teflon Tape | Smooth, non-stick, great for sealing threads | Not for hose repairs, only for threaded connections. |

Silicone tape is your best option for temporary fixes, but always replace the hose as soon as possible.

Does Tractor Supply10 sell hydraulic lines?

Yes, Tractor Supply10 does sell hydraulic lines, including hoses, fittings, and other related components. They offer both pre-assembled hoses and materials to create custom hydraulic lines.

Tractor Supply10 is a convenient source for hydraulic components, especially for agricultural and industrial applications.

Tractor Supply10 carries a range of hydraulic hose1s and fittings, catering primarily to agriculture, construction, and general industrial uses. Their selection includes various hose sizes and types, and they offer fittings to match. While they may not have the exact high-performance hoses used in heavy-duty industrial applications, they do provide basic hydraulic lines suitable for smaller or less demanding systems. If you need custom hose assemblies, they may also offer hose cutting services to your specifications.

Hydraulic Products at Tractor Supply10

| Product Type | Available at Tractor Supply10? |

|---|---|

| Pre-assembled hoses | Yes, available in standard lengths and fittings. |

| Hydraulic fittings | Yes, wide variety for different applications. |

| Custom hose cutting | Yes, in-store services for cutting to length. |

Tractor Supply10 is a reliable option for basic hydraulic components, but check the specifications for your needs.

Conclusion

Fixing a broken hydraulic hose1 depends on the type and extent of the damage. While methods like splicing or using tape can offer temporary solutions, the best course of action is to replace the hose or seek professional repair for high-pressure systems. Regular maintenance and proper inspection can help avoid hose failures in the first place.

-

Understanding maintenance can prolong the life of your hydraulic hose and prevent costly repairs. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how to effectively manage hydraulic hose emergencies to minimize downtime. ↩ ↩ ↩

-

Explore various repair methods to find the best temporary solutions for hydraulic hose issues. ↩ ↩

-

Learn about essential components of a hose repair kit to ensure you're prepared for emergencies. ↩

-

Explore strategies to prevent leakage and ensure the efficiency of your hydraulic systems. ↩

-

Learn why silicone tape is a preferred choice for temporary hydraulic hose repairs. ↩ ↩ ↩

-

Understand the importance of pressure testing for ensuring the reliability of hose repairs. ↩

-

Explore the services available at O'Reilly to assist with your hydraulic hose needs. ↩

-

Get tips on selecting a trustworthy hydraulic service provider for repairs. ↩

-

Discover the range of hydraulic components available at Tractor Supply for your projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩