Understanding the Power and Durability of Rebar Crimping Machines

The construction industry constantly seeks more efficient and reliable methods for reinforcing concrete structures. One such advancement is the rebar crimping machine, which has revolutionized how rebar connections are made, offering powerful crimping force and exceptional service life.

Rebar crimping machines provide a robust and durable method for connecting steel reinforcement bars in construction, offering significant advantages in terms of crimping force and service life over traditional methods. These machines ensure strong, permanent connections, enhancing the structural integrity and lifespan of buildings and infrastructure projects.

Rebar crimping machines are transforming the construction industry by providing a faster, more efficient method for connecting rebar.

What is a Rebar Crimping Machine?

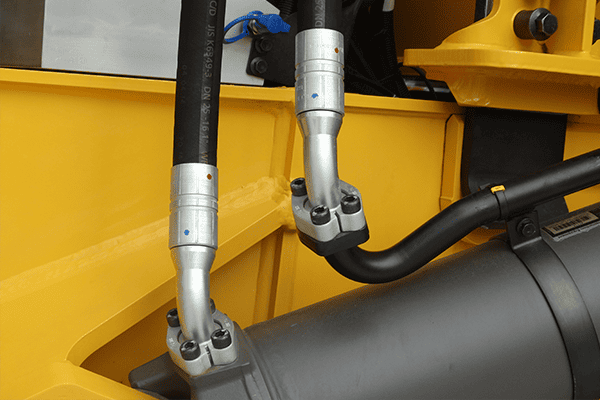

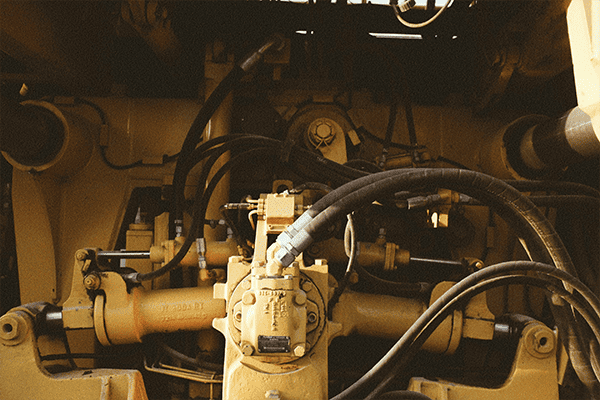

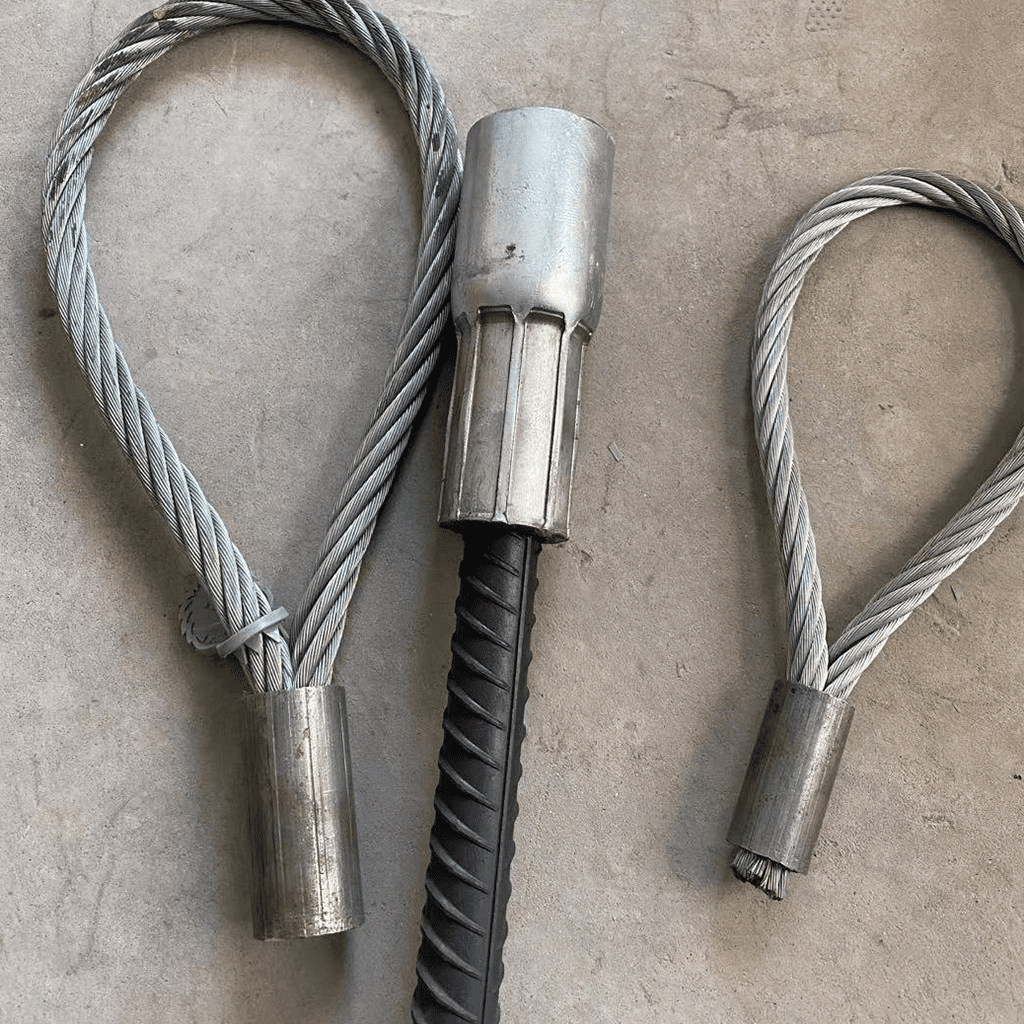

A rebar crimping machine is a specialized tool used to join steel reinforcement bars (rebars) in concrete structures. These machines apply a powerful hydraulic force to crimp a coupler around the bars, ensuring a secure and permanent connection. The primary components include a hydraulic pump, crimping head, and control unit, designed for precision and ease of use.

How Does a Rebar Crimping Machine Work?

The process begins by placing the rebar ends into a coupler, which is then positioned in the crimping head of the machine. Upon activation, the hydraulic pump exerts pressure, compressing the coupler around the rebar ends. This creates a strong, permanent bond capable of withstanding high tensile and compressive forces, crucial for maintaining the structural integrity of the construction.

Advantages of Using Rebar Crimping Machines

Rebar crimping machines offer several advantages over traditional methods like welding and lapping:

- Enhanced Crimping Force: The hydraulic system delivers consistent and powerful crimping force, ensuring a secure connection every time.

- Improved Efficiency: The process is significantly faster than welding or lapping, reducing labor time and costs.

- Cost-Effectiveness: By eliminating the need for overlap or welding materials, crimping reduces material wastage and overall project expenses.

- Reliability: The connections made by crimping machines are strong and durable, enhancing the longevity and safety of the structure.

Applications in the Construction Industry

Rebar crimping machines are versatile and used in various construction projects, including:

- Buildings: Ensuring the integrity of reinforced concrete structures.

- Bridges: Providing reliable connections in high-stress environments.

- Dams: Offering robust solutions for large-scale infrastructure.

- Towers: Enhancing the safety and durability of high-rise constructions.

Comparison with Traditional Methods

Traditional methods like welding and lapping have been the norm for rebar connections but come with drawbacks. Welding requires skilled labor and can be time-consuming, while lapping involves overlapping rebars, leading to material wastage and increased costs. Rebar crimping, on the other hand, provides a more efficient, cost-effective, and reliable alternative, making it the preferred choice in modern construction.

Choosing the Right Rebar Crimping Machine

When selecting a rebar crimping machine, consider the following factors:

- Crimping Force: Ensure the machine has adequate force for your specific application.

- Compatibility: Check that the machine can handle the sizes of rebar used in your projects.

- Durability: Its dies must be able to withstand such huge crimping force.

- Ease of Use: Choose a machine with user-friendly controls and safety features.

Maintenance and Service Life

Maintaining your rebar crimping machine is crucial for extending its service life. Regularly check the hydraulic system for leaks, ensure the crimping head is clean and free of debris, and follow the manufacturer's maintenance guidelines. Proper care and timely servicing will keep the machine in optimal condition, providing reliable performance for years.

Summary

Rebar crimping machines are a powerful and durable solution for connecting steel reinforcement bars in construction. Their enhanced crimping force, efficiency, and reliability make them an invaluable tool for industry professionals. By adopting this technology, construction projects can achieve greater structural integrity, cost savings, and improved safety.

For those looking to upgrade their rebar connection methods, rebar crimping machines offer a compelling option. Consider integrating this technology into your projects to reap the benefits of improved efficiency and durability.

If you have any questions or need further assistance in choosing the right rebar crimping machine for your needs, feel free to reach out.