Welcome to the world of crimping machines, where precision meets possibility. Picture this journey as a friendly conversation, where we navigate through the diverse classifications of crimping machines together. From the trusty reliability of manual models to the robust efficiency of hydraulic wonders, each category has its own story to tell. As we delve deeper, you'll discover the unique characteristics and capabilities of each type, helping you make informed decisions for your operations. So, let's embark on this exploration together, shedding light on the fascinating world of crimping machines with a touch of human warmth and understanding.

Crimping machines can be classified based on their power source into the following categories:Manual Crimping Machines,Pneumatic Crimping Machines,Electric Crimping Machines,Battery-Powered Crimping Machines. Classified by their machine head structure , it can be divided into the following categories: Thin Head Crimping Machines,Round Head Crimping Machines,Side-Opening Crimping Machines. Classified by their specific uses , it can be divided into the following categories: High-Pressure Hydraulic Hose Crimping Machines,Steel Pipe Crimping Machines,Terminal Crimping Machines,Heavy-Duty Crimping Machines.

Classified based on their power source

- Manual Crimping Machines: These machines are operated manually, typically by hand or foot pedal. They do not require any external power source and are suitable for applications where portability and simplicity are paramount.

- Pneumatic Crimping Machines: Powered by compressed air, pneumatic crimping machines offer fast and efficient crimping capabilities. They are commonly used in industrial settings where high-volume production and consistent performance are required.

- Electric Crimping Machines: Electric crimping machines are powered by electricity and often feature motorized mechanisms for crimping. They offer versatility and can be used for various crimping tasks, ranging from small-scale projects to high-volume production.

- Battery-Powered Crimping Machines: These portable crimping machines are powered by rechargeable batteries, providing flexibility and mobility in remote or on-site applications. They offer the convenience of cordless operation without compromising on performance.

Each type of crimping machine has its advantages and is chosen based on factors such as the nature of the crimping task, desired efficiency, portability requirements, and available power sources.

Classified based on their machine head structure

- Thin Head Crimping Machines: These crimping machines feature a slim and compact head design, allowing them to access tight spaces or narrow connectors with ease. They are suitable for applications where space is limited or where precise crimping in confined areas is required.

- Round Head Crimping Machines: Crimping machines with round heads have a circular or rounded crimping area. This design provides a uniform distribution of crimping force around the terminal, ensuring a secure and consistent crimp connection. Round head crimping machines are versatile and commonly used for hydraulic hose,steel pipe etc..

- Side-Opening Crimping Machines: In these crimping machines, the crimping head features a side-opening design. This allows for easy insertion and removal of wires and terminals from the side, simplifying the loading and unloading process. Side-opening crimping machines are particularly useful for applications where frequent changes of wire and terminal are required or for handling long wire lengths.

By considering the machine head structure, users can select the most appropriate crimping machine based on their specific application requirements, including space constraints, crimping precision, and ease of operation.

Classified by their specific uses

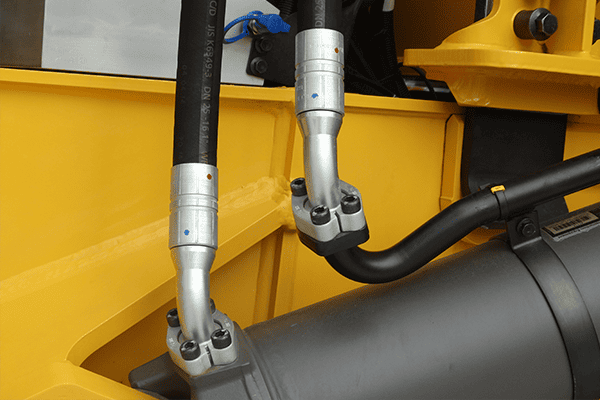

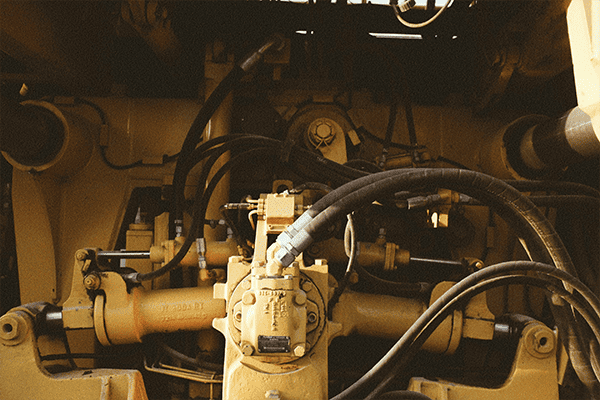

- High-Pressure Hydraulic Hose Crimping Machines:

- These machines are designed specifically for crimping high-pressure oil hoses used in hydraulic systems, such as those found in heavy machinery, construction equipment, and hydraulic systems in various industries.

- They are capable of applying significant force to create strong and leak-proof connections in high-pressure hydraulic systems, ensuring safety and reliability in demanding applications.

- Steel Pipe Crimping Machines:

- Steel pipe crimping machines are used for crimping steel pipes, tubes, or Greenhouse main architecture connection,Building scaffolding,Cement grouting pipe.

- They facilitate the joining of steel pipes by deforming or compressing the pipe ends to create a secure and durable connection, eliminating the need for welding or soldering.

- Heavy-Duty Crimping Machines:

- Heavy-duty crimping machines are designed to handle large or heavy-duty crimping tasks across various industries, including automotive, aerospace, construction, and manufacturing.

- These machines are capable of crimping thick wires, cables, rebar,wirerope or connectors with high precision and force, making them suitable for demanding applications that require robust and reliable crimped connections.

Each type of crimping machine serves specific industries and applications, providing efficient and reliable solutions for various crimping needs. By choosing the appropriate type of crimping machine based on the intended application, users can ensure optimal performance and quality in their crimping processes.