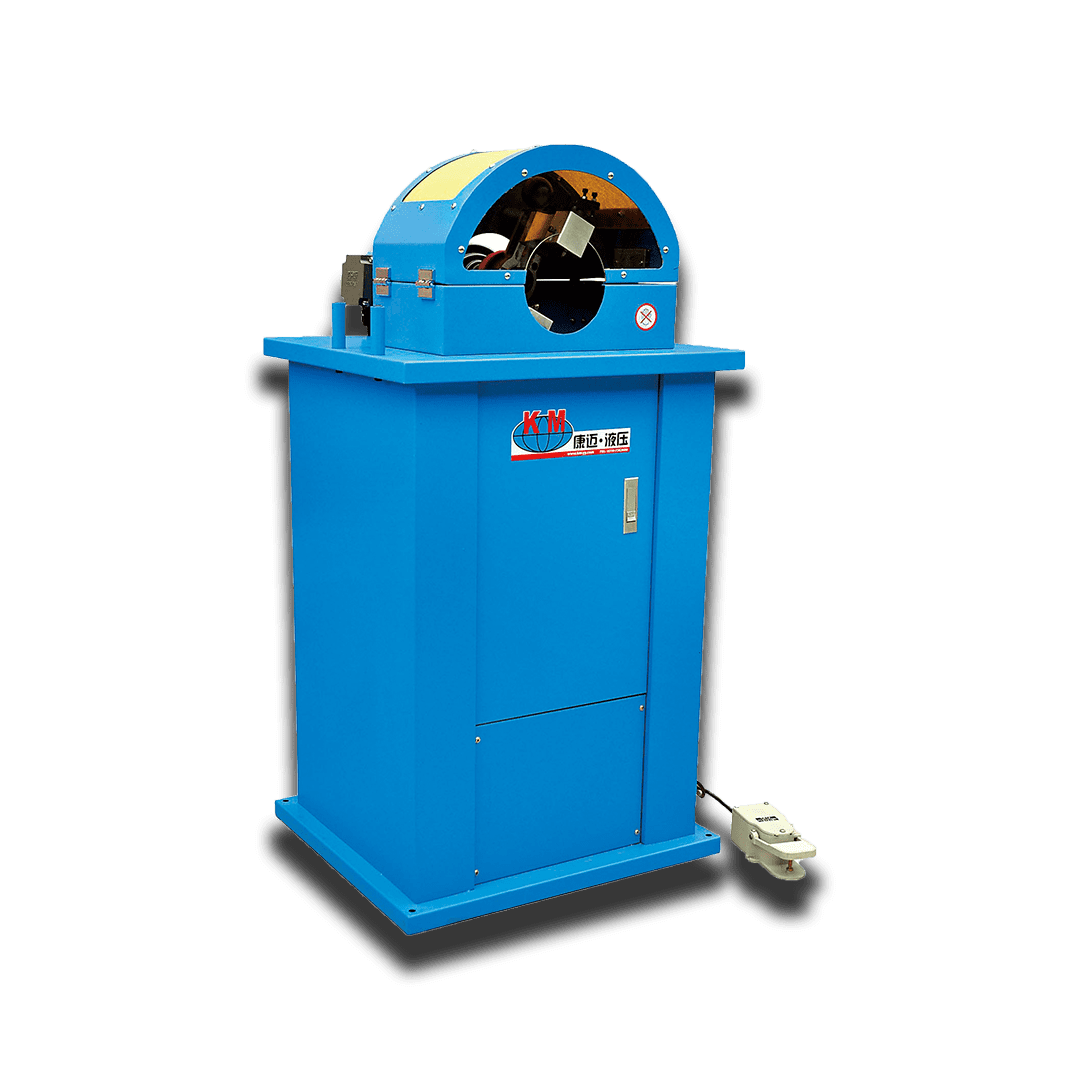

Your Premier Wholesale Partner for Hydraulic Hose crimping machine

Our Partners

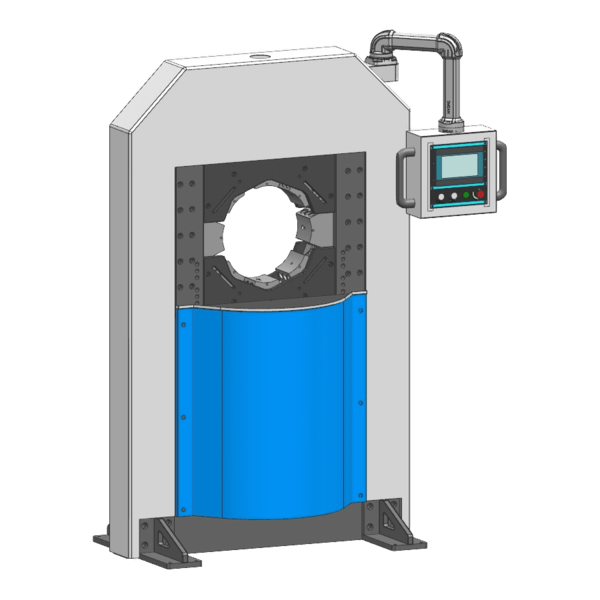

Select Your Ideal Hydraulic Machinery

Industry customization cases

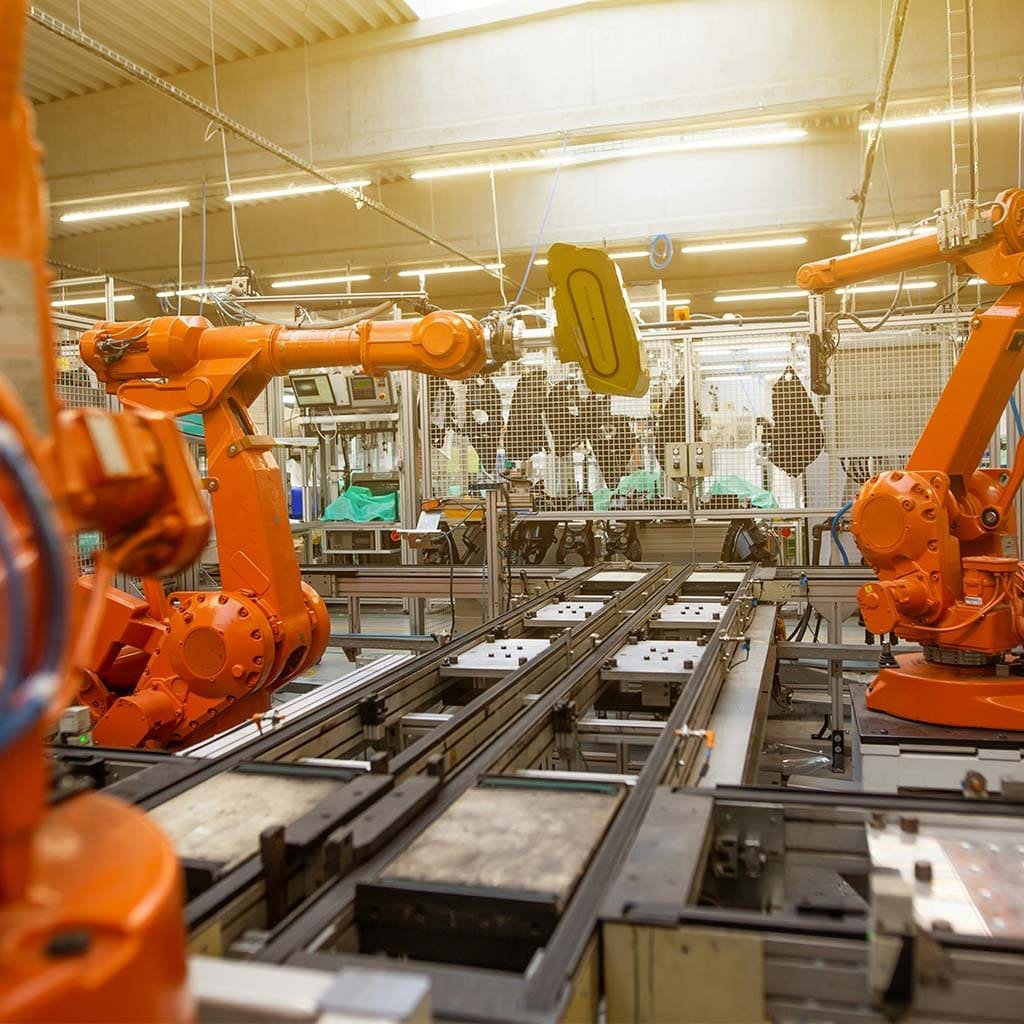

These use cases demonstrate the versatility and essential role of hose crimping machines in various sectors, emphasizing their importance in safety, maintenance, and manufacturing processes where secure hose connections are paramount. Kangmai’s hose crimping machines are designed to meet these diverse needs with reliability and efficiency.

Hydraulic Systems

- Maintenance of Heavy Machinery: Crimping machines are vital for the repair and assembly of hydraulic hoses that power construction and agricultural equipment.

- Production of Hydraulic Assemblies: They are used in the production of custom hydraulic hose assemblies for industrial machinery, ensuring they can withstand high pressures.

Automotive Industry

- Assembly of Brake Lines: Hose crimping machines are used to attach metal fittings to brake line hoses, ensuring a secure and leak-proof connection critical for safety.

- Manufacturing of Fuel Lines: They crimp hose fittings onto fuel hoses, which are essential for delivering fuel from the tank to the engine without leaks.

Oil and Gas Industry

- Oilfield Equipment Setup: Crimping machines are used to prepare hoses that can handle the extreme pressures found in oil extraction and transport processes.

- Refinery Maintenance: They are employed for the maintenance and creation of hoses used in oil refineries, which require robust and reliable hoses for various fluids and gases.

Aviation Industry

Aircraft Manufacturing: It is used to create and maintain the hoses used in aircraft hydraulic systems, which require precision and reliability due to the high standards of the aviation industry.

Construction Industry

Building embedded parts:Our crimping machines are the great choice for crimping the steel bars of embedded parts in buildings together with couplers, or for producing cement grouting pipes

Emergency Services

Firefighting Equipment: Crimping machines are crucial in assembling hoses for firefighting equipment, ensuring that hoses have secure connections for high-pressure water delivery.

Experience Unparalleled Quality and Customization in Every Product

Customizable Equipment

Our machinery can be tailored to your specific requirements, ensuring you get the exact solution you need for your unique challenges.

OEM Support

We provide comprehensive OEM support, enabling you to integrate our top-quality machinery seamlessly into your product lineup.

Global Export Expertise

With a strong presence in North America, Southeast Asia, the Middle East, Russia, and Australia, we understand the nuances of global markets and cater to them effectively.

Absolutely. We can customize hose crimping machines to fit specific requirements, such as crimp force, opening diameter, and control type, ensuring that you get a machine tailored to your specific needs.

We offer several types of hose crimping machines, including manual, electric. Classify by machine features: side feeding crimping head,particularly narrow crimping head,standard crimping head.Each type is designed to meet specific operational needs and production volumes.

Consider the type of hoses you will be crimping, the volume of work, the crimping force required, and the operational environment. Our experts can guide you through selecting the perfect machine for your application.

Regular maintenance includes cleaning the machine, lubricating moving parts, checking hydraulic fluid levels, and inspecting dies for wear. We provide detailed maintenance guides with every purchase.

Yes, we provide comprehensive training sessions for operators to ensure they understand how to safely and efficiently use the equipment. Training can be conducted at our facility or on-site, depending on your needs.

Our after-sales support includes technical assistance, spare parts supply, and repair services. We ensure that you have uninterrupted operations with minimal downtime.

Contact us directly through our website, email, or by phone. Our sales team will assist you with product selection, customization, and pricing information.

Yes, we have a strong global presence and can ship our hose crimping machines to North America, Southeast Asia, the Middle East, Russia, Australia, and other regions.

Call Now

+86 17732058136

Operating Hours

08.30 AM - 05.00 PM

Location

Handan, China

Connect with KANGMAI Today

Leave your contact information and we will have professional technicians to provide you with the most suitable hydraulic solution for free