At Kangmai Company, we stand at the forefront of hydraulic equipment innovation, distinguished by our unwavering commitment to quality and customer satisfaction. Our brand is synonymous with durability, reliability, and precision, offering a comprehensive range of top-tier hose crimping machines, cutting machines, and more, tailored to meet the diverse needs of our global clientele. With state-of-the-art technology and a keen eye for customization, we ensure our equipment is not only high-performing but also adaptable to specific customer requirements, supporting OEM. Kangmai’s strategic approach to manufacturing, combined with our extensive experience in the industry, allows us to provide equipment that enhances operational efficiency and safety across various sectors. By choosing Kangmai, customers gain a partner dedicated to excellence, innovation, and the kind of after-sales support that makes a real difference. We take pride in facilitating seamless operations for businesses around the world, solidifying our position as a trusted leader in the hydraulic equipment market.

Classification of hose crimper

Kangmai Company leverages cutting-edge technology and engineering expertise to deliver unparalleled technical advantages in the hydraulic equipment sector. Our products, including hose crimping machines, hose cutting machines, and more, are designed with precision and built to last, embodying the pinnacle of durability and performance. We innovate continuously, integrating smart technologies and automation to enhance efficiency and ease of use, making our equipment not just powerful but also user-friendly. Kangmai’s commitment to research and development means we stay ahead of industry trends, offering machines that are both highly customizable and capable of meeting the rigorous demands of diverse applications. With a focus on safety and sustainability, our equipment is engineered to reduce environmental impact while maximizing productivity. Kangmai’s technical excellence ensures our clients receive state-of-the-art solutions that drive their businesses forward.

OUR ADVANTage

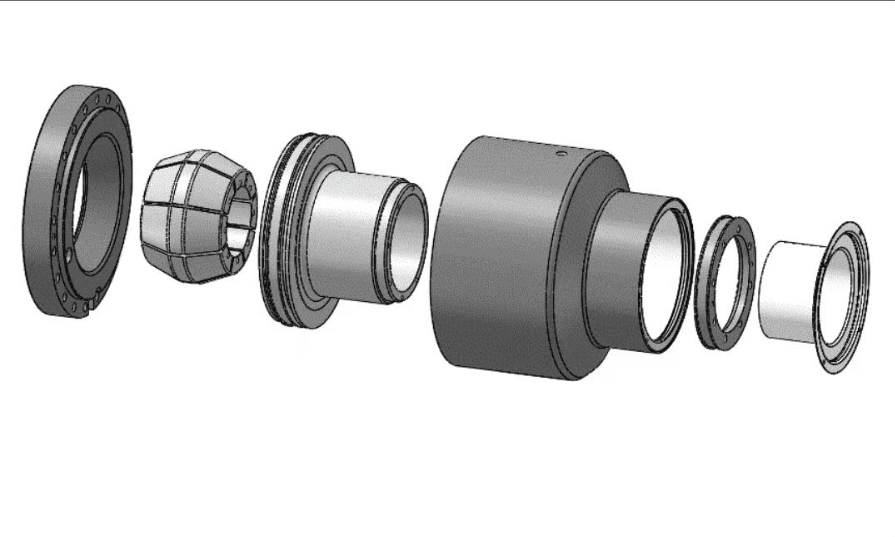

Exquisite cylinder design

Its new design uses a composite oil cylinder, eliminating the traditional machine controlled opening of two small oil cylinders.It has two oil chambers, one to control crimping and the other to control opening. This design makes the machine run more smoothly.And due to the reduction of connection points, its leakage points have also been reduced, greatly improving the reliability of the machine.

Secondly, the machine uses a dual cone design. It greatly reduces the friction coefficient, thereby improving the transmission efficiency of 30% force.And this design is also convenient for maintenance and upkeep.Improved work efficiency and reduced processing costs.

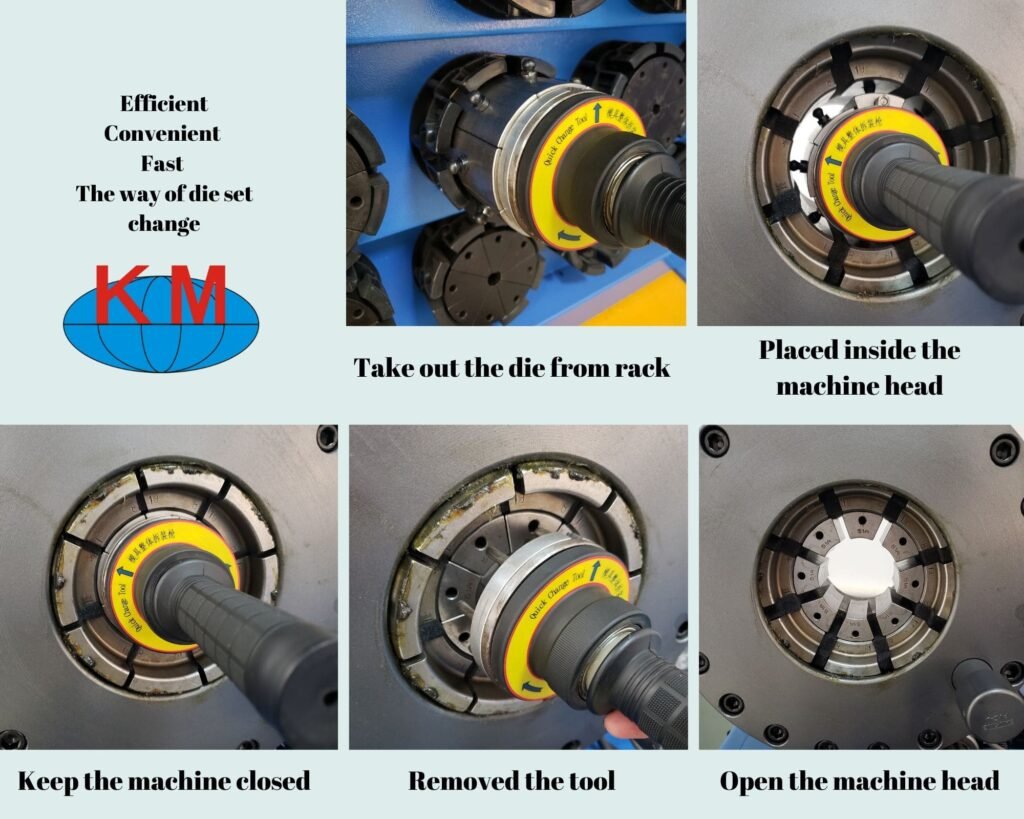

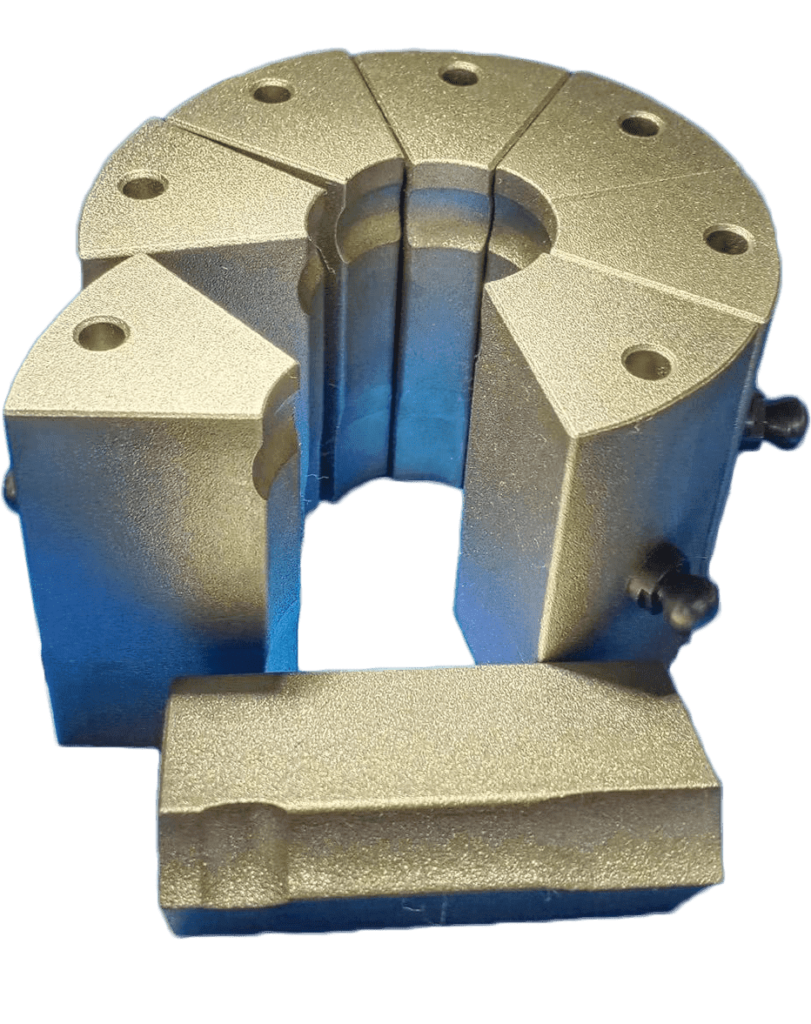

Self-designed quick die changing tool.

A self-designed and developed quick die changing tool. Its unique positioning makes it perform even better.Whether you are a beginner or an experienced worker, you can quickly adapt to it.Now let’s introduce its usage method to everyone.

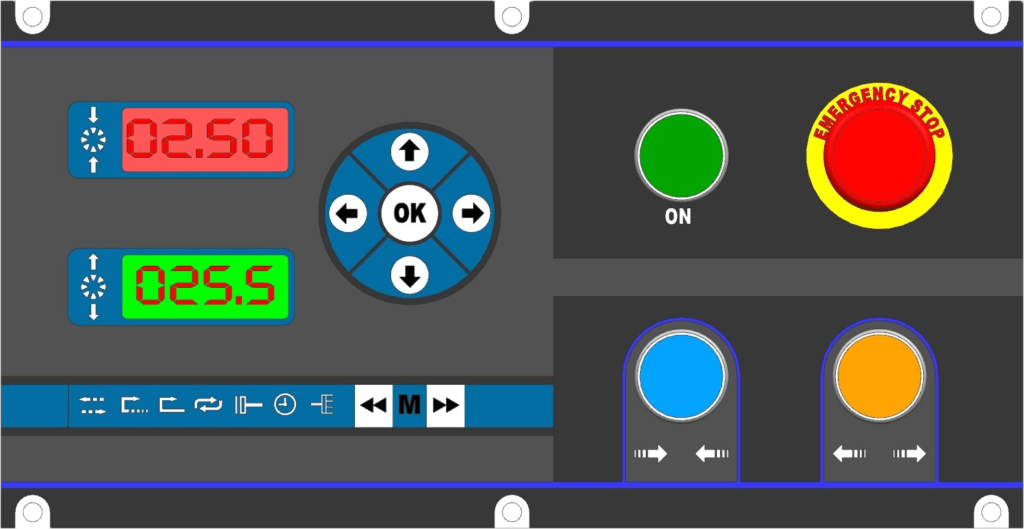

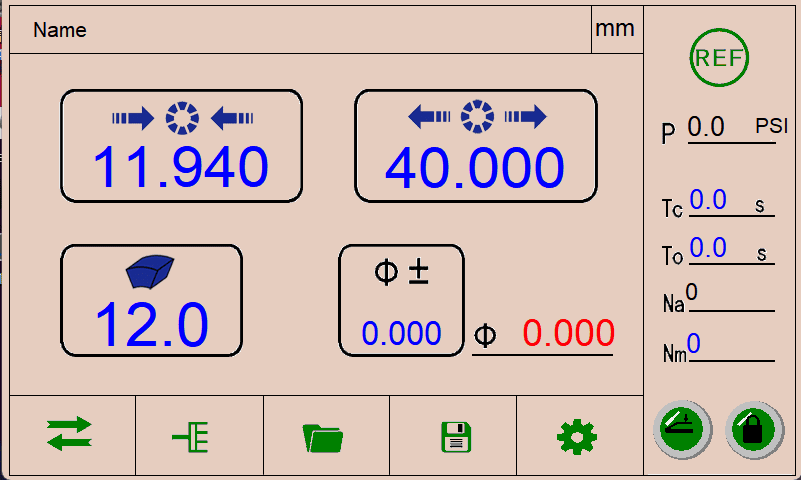

A simple and easy to learn operating system

We surveyed 200 users of crimping machines on their operating habits. Based on the information we got, we independently developed our control system.Our control system has multiple modes to choose from, allowing it to meet a wider range of usage scenarios.

CNC system

Supports 7 operating modes.

Manual mode

Return automatically mode

Semi-automatic modeAutomatic mode

Trigger switch mode

Time delay mode

Quick change mode.

Its operation is also very simple and it is suitable for use in various working conditions.

Touch screen system

Supports 8 operating modes.

Manual mode

Semi-automatic mode

Automatic mode

Trigger switch mode

Segmented crimp mode

Time delay mode

Quick change mode

Crimping data storage

Supports storage of up to 1000 pieces of data.

System Language Selection

You can set the system display language by yourself.

Safety function

The screen can be locked to prevent accidental touch.The foot switch can also be used or deactivated to prevent accidental operation.

More optional features

Pressure control.

Rear view camera.

Connecting with other management systems.

More durable dies

From the selection of raw materials to the final inspection and warehousing.Our employees are very dedicated to every step of the process.Because we need to ensure that the machines we produce are of high quality.

Our die uses a new vacuum heat treatment technology.During the heating process of the die, the oxidation reaction between the metal and oxygen is blocked. Make the surface of our die very smooth and even.

We have purchased a batch of machining centers specifically to ensure the high precision and quality of the dies.