Frustrated with poor hydraulic connections? A hydraulic crimper is your ultimate tool for perfect hose assemblies.

A hydraulic crimper assembles hoses by tightly compressing fittings, ensuring leak-proof and secure connections.

Explore this guide to master hydraulic crimpers and improve your operations seamlessly.

How does a hydraulic hose crimper work?

Hydraulic hose crimpers operate by compressing fittings onto a hose, forming a strong and reliable connection.

The tool uses high pressure to deform the fitting, creating a tight seal with the hose.

Understanding the Crimping Process

The crimping process involves three simple steps:

| Step | Action | Key Point |

|---|---|---|

| Preparation | Measure and cut the hose properly | Ensure the correct length |

| Setup | Insert the fitting into the crimper | Select the correct die size |

| Crimping | Activate the machine | Verify crimp dimensions |

Learn more about hydraulic crimping best practices1.

What is the best way to use a crimper?

Avoid mistakes and maximize efficiency by following best practices while using your hydraulic crimper.

Always inspect the machine, use recommended settings, and double-check your fittings and hoses.

Key Tips for Best Results

- Inspect Tools Regularly: Clean and maintain your crimper for consistent performance.

- Follow Manufacturer’s Guidelines: Adhere to pressure settings and die sizes.

- Test Before Use: Conduct a test crimp on scrap material.

Explore detailed tips on maintaining hydraulic equipment2.

What does a hydraulic crimper do?

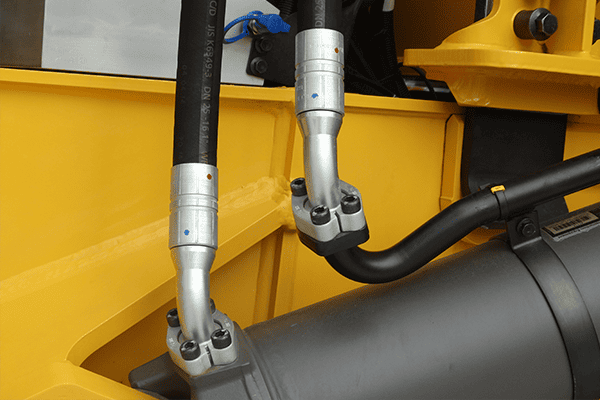

A hydraulic crimper secures hoses by permanently attaching fittings using high pressure.

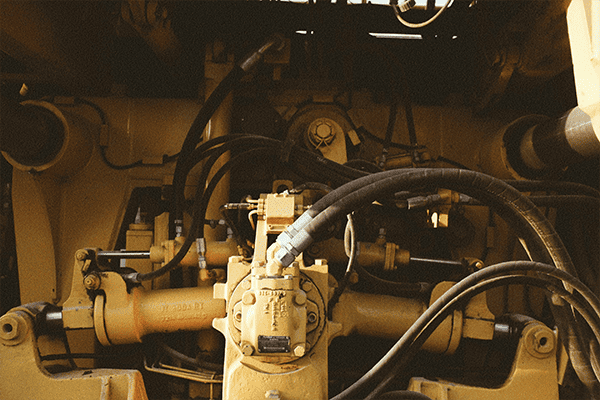

This tool is essential in industries like construction, manufacturing, and automotive for leak-proof connections.

Key Applications of Hydraulic Crimpers

Hydraulic crimpers are used in:

| Industry | Common Applications |

|---|---|

| Construction | Heavy machinery and excavator hoses |

| Manufacturing | Hydraulic presses and automation lines |

| Automotive | Power steering and brake line assembly |

Understand the role of hydraulic crimpers 3 in various industries.

What is the difference between a hand crimper and a hydraulic crimper?

Hand crimpers rely on manual force, while hydraulic crimpers use pressurized fluid for power.

Hydraulic crimpers are ideal for high-volume, precise tasks, whereas hand crimpers suit small-scale projects.

Comparison of Hand and Hydraulic Crimpers

| Feature | Hand Crimper | Hydraulic Crimper |

|---|---|---|

| Power Source | Manual effort | Hydraulic pressure |

| Precision | Moderate | High |

| Efficiency | Low for large projects | Excellent for high volume |

Learn about choosing the right crimper4 for your needs.

How to use a hydraulic crimper?

Using a hydraulic crimper involves preparation, setup, and execution.

Measure the hose, insert the fitting, choose the right die, and let the crimper do its job.

Step-by-Step Guide

- Prepare the Hose: Cut the hose to the required length and clean the ends.

- Select the Right Die: Match the die size to your fitting and hose diameter.

- Insert the Fitting: Place the fitting in the hose and position it in the crimper.

- Activate the Crimper: Use the machine to crimp, ensuring uniform pressure.

- Inspect the Crimp: Check the crimp for alignment and seal integrity.

Find more details in this step-by-step hydraulic crimping guide5.

Can you over crimp a hydraulic hose?

Yes, over-crimping can damage the hose and fittings, leading to leaks or failures.

Excessive pressure may deform the fitting or hose, compromising the connection.

How to Avoid Over-Crimping

- Calibrate the Machine: Regularly check pressure settings.

- Use Manufacturer-Approved Dies: Incorrect dies can result in improper crimping.

- Inspect Each Crimp: Verify dimensions using a gauge or measurement tool.

Learn how to prevent over-crimping issues6.

Conclusion

Hydraulic crimpers are essential for creating secure and efficient hose assemblies. By mastering their use and following best practices, you'll enhance productivity and reduce downtime.

-

To improve the effectiveness and reliability of crimping operations. ↩

-

Helps ensure long-term performance and reduce maintenance costs. ↩

-

To understand where hydraulic crimpers are indispensable. ↩

-

Helps in choosing the right tool for specific tasks. ↩

-

Detailed instructions for consistent and accurate crimping. ↩

-

Ensures proper technique and prevents connection failures. ↩