Finding the right hydraulic hose1 can be confusing, but choosing wisely ensures safety and efficiency.

Selecting the proper hydraulic hose requires understanding size, material, and pressure needs. Make an informed choice.

Explore the essentials below to pick the perfect hydraulic hose for your machinery.

How to Select a Hydraulic Hose?

Choosing the wrong hose can lead to leaks or damage. Understand key factors to make the right decision.

Focus on compatibility with pressure, temperature, and materials for optimal hydraulic performance.

When selecting a hydraulic hose, you must evaluate the following:

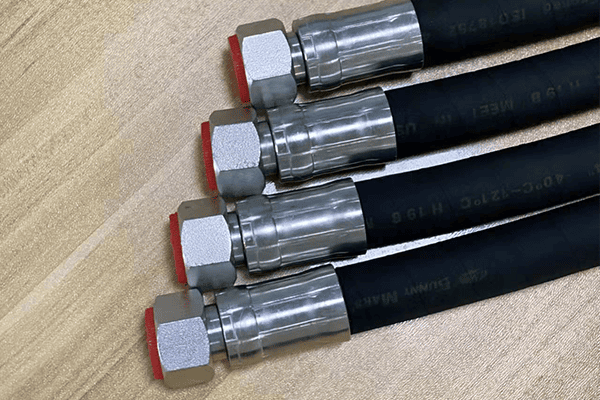

Consider the Material

| Hose Material | Best Use Case |

|---|---|

| Rubber | Flexible, suitable for high-pressure jobs |

| Thermoplastic | Lightweight, abrasion-resistant |

| Stainless Steel | High heat resistance, long lifespan |

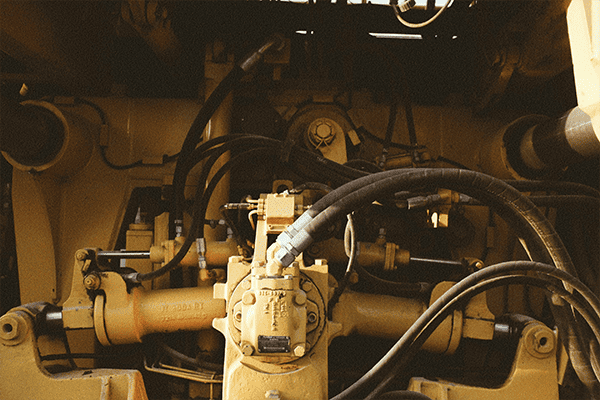

Match with the Application

For example, in construction, choose abrasion-resistant hoses. For industrial plants, prioritize heat-resistant ones.

How Do I Know What Size Hydraulic Hose I Need?

Incorrect sizing can affect performance. Learn how to measure for accuracy.

Measure both the internal diameter and length2 to match equipment requirements.

Measure the Internal Diameter

Use a caliper to measure the hose's internal diameter. This ensures proper fluid flow without excess resistance.

Account for Length and Flexibility

Include enough length for movement. Avoid over-tight bends to reduce wear.

Sizing Chart Reference

| Hose Diameter (inches) | Common Uses |

|---|---|

| 1/4" | Low-pressure systems |

| 1/2" | Medium-pressure industrial equipment |

| 1" | High-pressure applications |

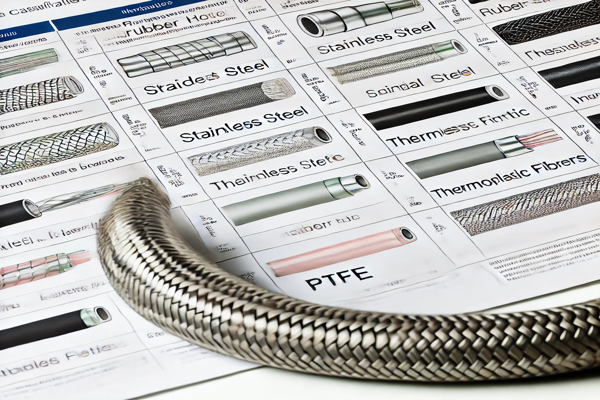

What is the Best Type of Hydraulic Hose?

Not all hoses are created equal3. Each has unique strengths and weaknesses.

The best hose depends on your equipment and application. Compare options to find the perfect match.

Popular Hydraulic Hose Types

- SAE 100R1: Flexible, cost-effective for low-pressure systems.

- SAE 100R2: Durable, handles medium to high-pressure conditions.

- Thermoplastic Hoses: Lightweight, great for mobile equipment.

Factors for Comparison

Consider these attributes:

- Pressure capacity

- Temperature resistance

- Compatibility with hydraulic fluids

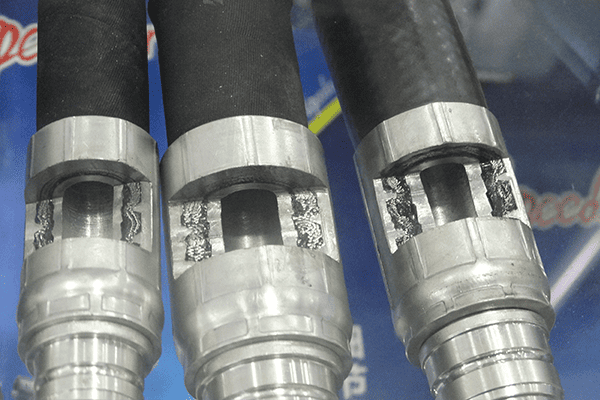

What are the Grades of Hydraulic Hoses?

Different grades handle varying pressure and environmental conditions. Understanding them helps avoid failure.

Hydraulic hoses are graded by pressure tolerance4, flexibility, and temperature limits.

Key Grades and Applications

| Grade | Pressure Range | Typical Use |

|---|---|---|

| Low-Pressure | <600 PSI | Return lines, ventilation |

| Medium-Pressure | 600-3000 PSI | Agriculture, construction |

| High-Pressure | >3000 PSI | Heavy machinery |

When to Upgrade

If a hose frequently bursts or degrades quickly, consider switching to a higher-grade hose.

How Do I Choose the Right Hose?

Making the right choice depends on matching the hose to your hydraulic system's specifications.

Match hose features with your system5, size, and fluid type for best results.

Steps to Follow

- Understand Pressure Needs: Identify maximum operating pressure.

- Check Material Compatibility: Ensure the hose material suits the fluid type.

- Consider Environmental Factors: Choose hoses resistant to external conditions like heat or abrasion.

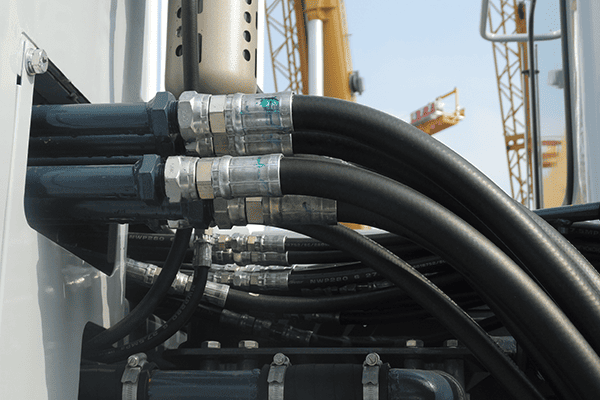

Practical Example

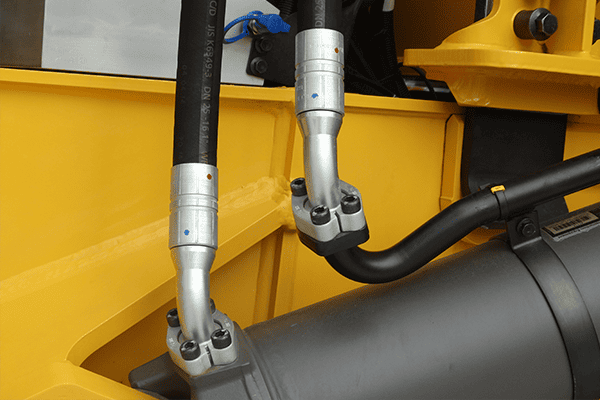

For high-pressure construction machinery, a reinforced steel-braided hose is ideal.

Which is Better: 1 Wire or 2 Wire Hydraulic Hose?

Wire reinforcement impacts strength and flexibility. Knowing when to choose each is crucial.

A 1-wire hose is more flexible6, while 2-wire hoses handle higher pressures.

Comparison of 1 Wire vs. 2 Wire

| Feature | 1 Wire | 2 Wire |

|---|---|---|

| Pressure Limit | Lower (<3000 PSI) | Higher (>3000 PSI) |

| Flexibility | More flexible | Less flexible |

| Cost | Lower | Slightly higher |

Choosing the Right Option

For light-duty applications, a 1-wire hose is sufficient. For heavy-duty tasks, go with a 2-wire hose to prevent failures.

Conclusion

Understanding hydraulic hose selection helps ensure safety, efficiency, and durability in your operations.

-

Learn how to choose a hydraulic hose for better safety and efficiency. ↩

-

Discover methods to accurately measure hydraulic hoses for your equipment. ↩

-

Compare hydraulic hose types to find one that matches your needs. ↩

-

Understand hydraulic hose grading to avoid mismatches or failures. ↩

-

Learn to align hydraulic hose features with system needs for better results. ↩

-

Identify the appropriate use cases for 1-wire or 2-wire hydraulic hoses. ↩