Crimping braided brake lines requires precision and the right tools. If done improperly, it could compromise safety. Here's how to ensure a perfect crimp every time.

Crimping braided brake lines is essential for safety and performance. Use the right tools and follow precise steps for proper installation.

Safety is paramount when working with brake lines. If you're unsure, consider seeking professional assistance. But, if you want to take the DIY approach, this guide will walk you through it step-by-step.

Can You Clamp Braided Brake Lines?

Clamping braided brake lines is a common question. However, using clamps on these types of lines isn't recommended. Clamps may cause damage to the braided outer layer, leading to leaks or reduced pressure. It’s better to use crimp fittings to secure the line.

Clamping braided brake lines1 can cause damage and compromise safety. Always opt for crimping fittings instead.

Why Clamps Should Be Avoided

-

Damage to the Outer Layer

Braided lines are designed with a protective outer layer. Clamping can crush or wear down this layer, reducing the strength of the line. -

Risk of Leaks

Clamps often fail to provide the tight, consistent seal required for hydraulic systems, leading to brake fluid leaks. -

Pressure Loss

Clamps may not ensure an even, strong seal along the entire length of the fitting, which can cause a drop in brake pressure and affect overall performance.

Proper Methods for Securing Braided Brake Lines

- Crimping Fittings2: Crimping is the most reliable method to securely attach fittings to braided brake lines.

- Compression Fittings: These are an alternative that can provide a secure connection, but they’re generally less common for braided lines compared to crimp fittings.

Is There a Downside to Braided Brake Lines?

While braided brake lines offer many advantages, they also come with a few potential downsides. It's important to weigh these against the benefits before deciding on their use.

Braided brake lines offer durability, but they can be harder to install and maintain.

The Pros and Cons of Braided Brake Lines

Pros:

-

Durability

Braided brake lines are resistant to abrasion, ensuring long-term reliability. -

Enhanced Performance

They offer better resistance to pressure and temperature fluctuations, leading to improved brake performance. -

Flexibility

Unlike rubber hoses, braided lines are more flexible and easier to route around the vehicle.

Cons:

-

Installation Difficulty

Braided lines require precise crimping or compression for secure installation, making the process more complicated compared to traditional rubber lines. -

Cost

Braided brake lines tend to be more expensive than their rubber counterparts. -

Maintenance

Braided lines can be difficult to inspect for internal wear or damage. When they fail, it might not be as obvious as with rubber lines.

Can I Crimp a Brake Line?

Yes, you can crimp a brake line, but it requires the right equipment and technique. Crimping is commonly done on braided brake lines to ensure they’re securely connected to the fitting. A properly crimped brake line3 can last for years without issue.

Crimping is the preferred method to secure brake lines when done correctly.

Step-by-Step Guide to Crimping Brake Lines4

-

Prepare the Brake Line

Cut the line to the required length and expose the inner hose if using a braided line. -

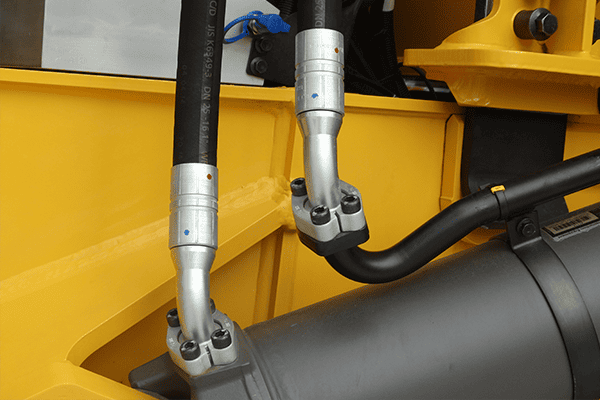

Select the Right Fitting

Ensure the fitting matches the size of the line and the crimping tool you’re using. -

Place the Line in the Fitting

Insert the brake line securely into the fitting, making sure it’s fully seated. -

Crimp the Fitting

Using a crimping tool, apply even pressure until the fitting is tightly secured to the brake line. -

Inspect the Crimp

Check for a solid, flush crimp with no gaps or leaks before moving on to testing the system.

How Do You Install Braided Brake Lines?

Installing braided brake lines requires care and attention to ensure there are no leaks or pressure loss.

Follow a few key steps to ensure your braided brake lines are properly installed for maximum performance.

Step-by-Step Installation of Braided Brake Lines

-

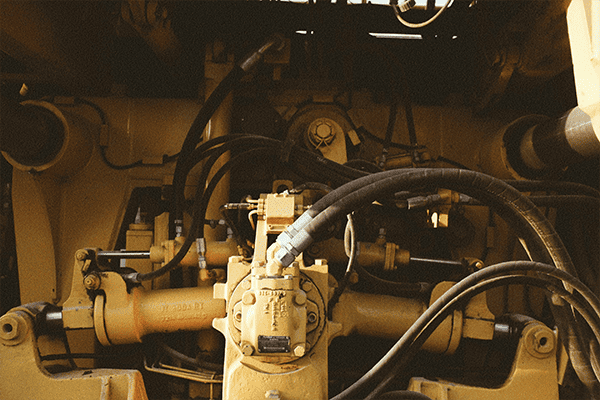

Prepare the Brake Line

Measure the length of the brake line you need, making sure to account for any bends or turns. -

Install the Fittings

Slide the fittings onto each end of the brake line. Ensure they are securely positioned before crimping or compressing. -

Route the Brake Line

Carefully route the braided line along the desired path, ensuring it doesn't kink or get damaged. -

Crimp the Fittings

Use a crimping tool to attach the fittings to the line securely. Ensure that the crimp is tight and the line is held firmly in place. -

Test for Leaks

Once installed, pressurize the brake system and check for any leaks. If there’s a leak, you may need to redo the crimping.

How Much Difference Do Braided Brake Lines Make?

Braided brake lines offer significant improvements in brake system performance, but they may not always be necessary for every driver.

Braided brake lines provide better performance, but their benefits may only be noticeable in specific conditions.

Benefits of Braided Brake Lines

-

Increased Durability

Braided lines are resistant to external damage like abrasions and cuts, which helps maintain performance over time. -

Improved Brake Response

Braided lines reduce expansion under pressure, ensuring a firmer brake pedal feel and more immediate response. -

Better Temperature Resistance

These lines can withstand higher temperatures, making them ideal for performance vehicles or environments where brake temperatures are high.

When Are Braided Brake Lines Most Useful?

- Racing and Performance Vehicles: The improved braking response and heat resistance make braided lines ideal for high-performance applications.

- Heavy-Duty Use: Vehicles that experience high brake system pressures benefit from braided brake lines' durability.

How Do You Put a Hook on a Braided Line?

Adding a hook to a braided line can help with installation or routing. It requires the right tools and technique to prevent damage to the line.

Attaching a hook to a braided line requires precision to avoid damaging the protective outer layer.

Steps to Adding a Hook

-

Select the Right Hook

Choose a hook designed for braided lines. It should be strong enough to hold the line but gentle enough to avoid damaging the outer braid. -

Prepare the Line

Gently pull back the braided material at the point where the hook will be attached. Make sure not to damage the inner hose. -

Secure the Hook

Attach the hook at the appropriate location and ensure it’s properly secured. Avoid over-tightening as this can crush the braid. -

Check the Line

After adding the hook, inspect the line for any signs of stress or damage. Ensure the line remains flexible and undamaged.

Conclusion

Crimping braided brake lines requires the right tools and attention to detail. By following proper procedures, you can achieve a secure and durable connection that will last for years.

-

Learn why clamps can damage the brake line and affect safety. ↩

-

Crimp fittings provide secure connections in hydraulic systems. This link explains their role. ↩

-

Understand the benefits of braided brake lines, including performance and durability. ↩

-

This guide will walk you through how crimping works for brake lines. ↩