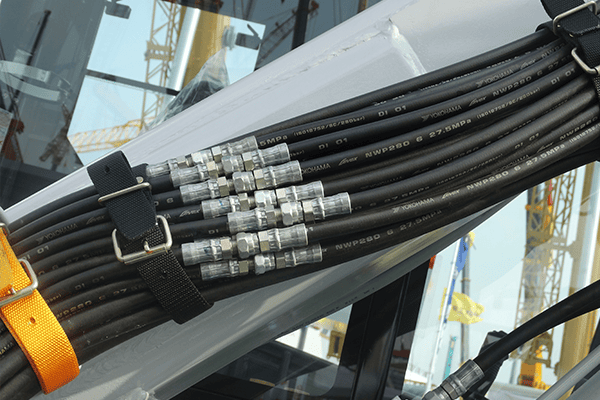

After crimping a hydraulic hose, it’s essential to inspect the crimping quality to ensure that it’s secure and leak-proof. A poorly crimped hose can lead to system failures, leaks, and even catastrophic accidents.

Judging the quality of a crimp involves checking for uniformity, correct dimensions, and the absence of defects that could compromise the hose's performance.

Transition paragraph: Let’s walk through the key steps to evaluate whether your hydraulic hose is properly crimped and how to avoid common mistakes.

Can you over crimp a hydraulic hose?

Yes, it is possible to over crimp a hydraulic hose. Over crimping occurs when the hose is compressed beyond the recommended dimensions, which can damage the hose, reduce its pressure capacity, and create a potential leak point.

Over crimping can weaken the hose and fittings, reducing the hose's overall performance and lifespan.

Over crimping typically happens when the crimping tool is set to an incorrect pressure or when too many crimp cycles are applied. This can cause the hose to become deformed or squeezed too tightly, leading to internal damage. Over-crimped hoses can have a reduced internal diameter, causing flow restrictions and possibly rupturing under pressure. The crimped area may also show visible signs of damage, such as cracks or visible deformities, which affect the hose's durability.

Consequences of Over Crimping

| Issue | Description |

|---|---|

| Internal Damage | Over-compression of the hose could cause internal breakdown. |

| Reduced Flow | Narrowed inner diameter due to over-crimping could restrict flow. |

| Premature Failure | Increased risk of leaks[^1] and failures under pressure. |

Careful monitoring of crimping pressure is essential to avoid these issues.

How to check crimping?

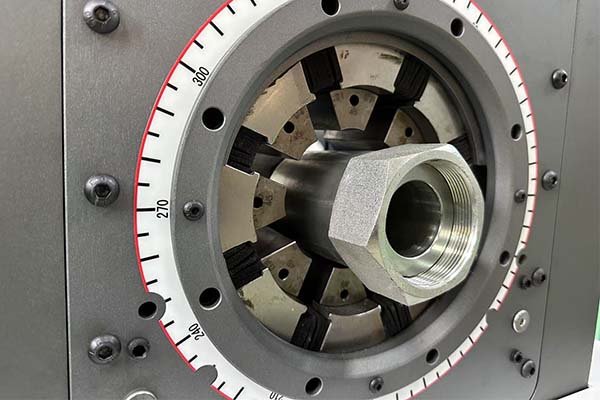

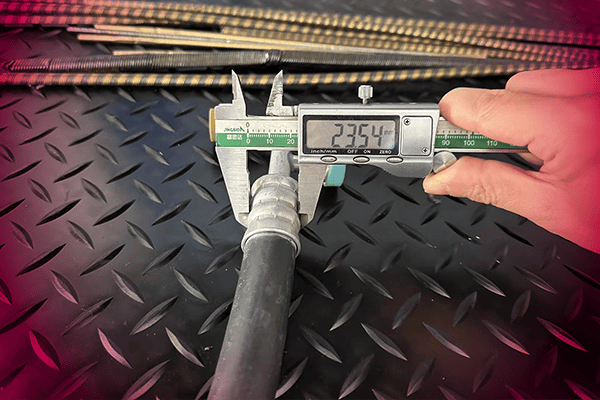

To check the crimping quality[^2], the most effective method is to use a caliper or micrometer[^3] to measure the crimped section’s outside diameter (OD) and compare it to the manufacturer’s specifications.

A correct crimp will show uniformity, accurate dimensions, and no visible damage to the hose or fittings.

First, measure the crimped area with precise measuring tools like a digital caliper[^4]. The crimp’s outer diameter (OD) should match the values specified by the manufacturer for the type of hose and fitting used. The crimp should also have a smooth, even appearance without any visible deformities. If there’s any damage like cracks, gaps, or distortion, the hose should not be used. Additionally, make sure the crimping is consistent across the entire length of the fitting to prevent weak points.

Key Steps to Check Crimping

| Step | Action |

|---|---|

| Measure OD | Use a caliper[^4] to measure the outer diameter of the crimped section. |

| Inspect for Damage | Look for cracks, gaps, or other visible issues in the crimp. |

| Check Fitting Alignment | Ensure the fitting is centered and aligned properly with the hose. |

Proper inspection ensures the hose meets safety and performance standards.

What is the tolerance of a hose crimp?

The tolerance of a hose crimp[^5] refers to the allowable variation in the crimp's dimensions. For most hydraulic hoses, the tolerance should fall within a specific range, usually ±0.1mm to ±0.3mm, depending on the hose and fitting specifications.

Ensuring that the crimp falls within the proper tolerance is critical for maintaining system integrity and preventing leaks[^1].

Tolerances are vital for ensuring that the crimped hose provides a secure connection. If the crimp is too loose, it may cause leaks[^1], while an over-crimped hose might restrict fluid flow or damage the hose. Typically, hydraulic hose manufacturers provide a crimp chart or guidelines with specific tolerances for various hose and fitting combinations. It’s essential to follow these guidelines closely to ensure consistent, high-quality crimps across all assemblies.

Crimp Tolerance Guidelines

| Hose Size | Tolerance Range | Common Issue |

|---|---|---|

| 1/4" | ±0.1mm | Over-crimping or under-crimping can lead to leaks[^1]. |

| 1/2" | ±0.2mm | Poor tolerance can restrict fluid flow or weaken the hose. |

| 1" | ±0.3mm | Loose crimps may cause hose disconnection or leaks[^1]. |

Consistent crimp tolerances ensure that the hose assembly is safe and durable.

What is the common defect in the hydraulic hose?

The most common defects in hydraulic hoses after crimping include under-crimping[^6], over-crimping, improper alignment of the hose and fitting, and visible damage to the hose cover.

These defects can significantly impact the hose's performance and safety.

Common defects like under-crimping[^6] often occur when the crimp tool isn’t set to the correct pressure, leaving the fitting not securely attached to the hose. Over-crimping can cause damage to both the hose and fitting, leading to potential leaks[^1] and system failure. Misalignment between the fitting and the hose can also weaken the crimp, leading to leaks[^1] or premature hose failure. Finally, damage to the hose cover, such as cuts or abrasions, can compromise the hose’s ability to resist environmental threats, such as UV rays, heat, and chemicals.

Common Defects in Hydraulic Hose Crimping

| Defect | Description |

|---|---|

| Under-crimping | The fitting is not compressed enough, leading to leaks[^1]. |

| Over-crimping | Excessive compression, damaging the hose or restricting flow. |

| Misalignment | Fittings not aligned with the hose, causing weak spots. |

| Cover Damage | Abrasions or cuts in the outer hose layer reducing its resistance. |

Regular inspections can prevent these issues from compromising hydraulic hose performance.

What happens if you over crimp?

Over crimping a hydraulic hose can cause the fitting to compress the hose too tightly, leading to reduced inner diameter, compromised structural integrity, and the potential for leaks[^1].

Over crimping reduces the hose’s performance, leading to safety issues and premature failure.

The most significant problem with over crimping is the restriction of fluid flow caused by the reduced inner diameter. This can cause increased pressure within the system, leading to ruptures or leaks[^1]. The fitting may also become deformed, preventing it from making a proper seal. In extreme cases, over crimping[^7] can lead to the failure of the entire hydraulic system. Therefore, it is essential to use the correct crimping pressure[^8] and monitor the crimp during the process.

Problems Caused by Over Crimping

| Issue | Result |

|---|---|

| Reduced Flow | Decreased internal diameter limits fluid movement. |

| Leakage | Deformed fittings and hoses create weak points. |

| Premature Failure | Over-crimping weakens the hose, leading to breakage. |

Using the right crimping pressure ensures a secure, leak-free connection.

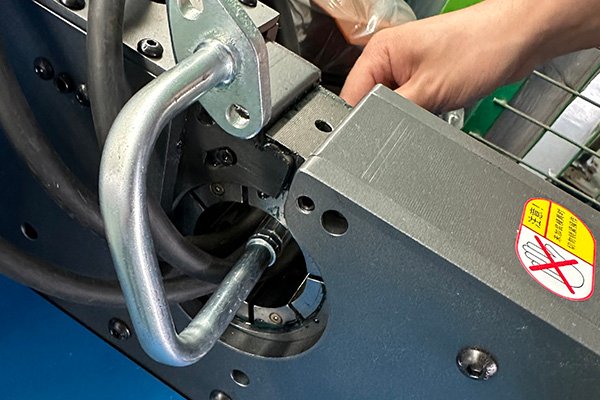

How do you crimp a hose?

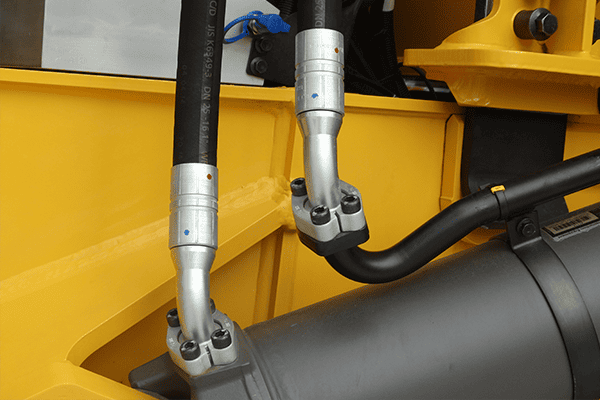

Crimping a hose involves using a crimping tool[^9] to compress a fitting onto the hose, ensuring a secure and leak-free connection. The process requires selecting the right hose, fitting, and crimping tool[^9], then following the manufacturer’s guidelines for crimp size[^10].

The crimping process should be precise to ensure the hose and fitting are securely attached and can withstand high pressures.

Begin by cutting the hose cleanly and ensuring both the hose and fittings are compatible. Place the fitting onto the hose end, ensuring it is seated correctly. Insert the hose and fitting into the crimping tool[^9], then close the tool until it applies the correct amount of pressure. After crimping, measure the outer diameter of the crimped section and compare it to the manufacturer’s specifications. Finally, inspect the crimped hose for damage, proper fit, and alignment.

Crimping Steps

| Step | Action |

|---|---|

| Select Hose & Fitting | Ensure compatibility with the system requirements. |

| Insert into Tool | Secure the hose and fitting in the crimping machine. |

| Apply Crimp | Use the crimping tool[^9] to apply uniform pressure. |

| Measure & Inspect | Check the crimp’s diameter and quality. |

Proper crimping ensures safe and efficient operation of hydraulic systems.

Conclusion

To ensure a hydraulic hose is properly crimped and qualified, check for correct crimping pressure[^8], precise measurements, and the absence of defects like cracks or leaks[^1]. Regular inspection and accurate crimping practices are key to ensuring reliable hose performance.

---

[^1]: Identifying leak causes can help in maintaining the integrity of hydraulic systems.

[^2]: Understanding crimping quality is crucial for ensuring safety and performance in hydraulic systems.

[^3]: Explore how micrometers enhance precision in measuring crimp dimensions for safety.

[^4]: Learn the correct use of calipers to ensure accurate measurements for safe hose connections.

[^5]: Understanding tolerance is key to ensuring secure and leak-free hydraulic connections.

[^6]: Learn about the risks associated with under-crimping to avoid leaks and failures.

[^7]: Learn about the risks of over crimping to prevent costly failures and ensure system integrity.

[^8]: Knowing the right crimping pressure helps prevent damage and ensures optimal performance.

[^9]: Choosing the right crimping tool is vital for achieving secure and reliable hose connections.

[^10]: Understanding crimp size is crucial for ensuring compatibility and safety in hydraulic systems.