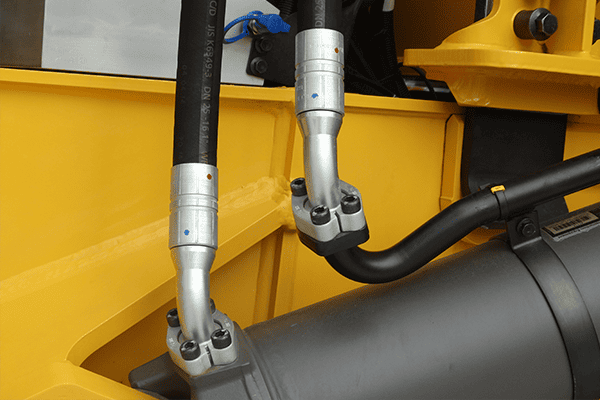

How to use a hose crimping machine ?

Using a hose crimping machine involves several steps to ensure a secure and effective crimp on the hose.

We should first do some preparation work. We need to first add hydraulic oil that meets the requirements to the machine after we purchase a new hose crimping machine and receive it. Because usually machines are not allowed to contain oil during transportation.

After adding oil, the next step is to connect the power supply. Before connecting power, it is necessary to ensure that the connected power supply is consistent with the power supply format marked on the machine nameplate.Otherwise, there is a risk of damaging the machine.

Please read the machine’s user manual carefully before carrying out specific operations.

So we can proceed with the operation.

Here’s a general guide:

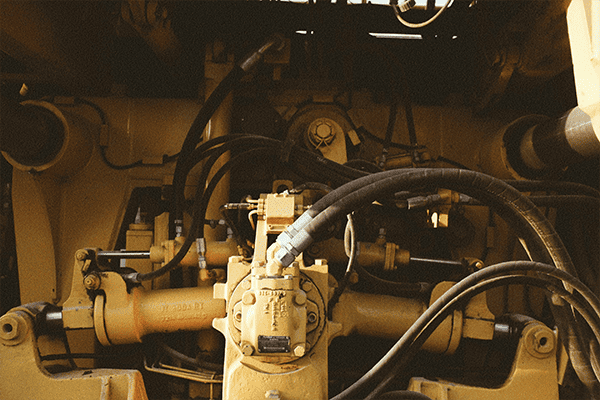

At the beginning, there was no device to adjust the crimping diameter of the crimping machine. The electronic control system was not perfect enough, and the opening and close of the machine relied on a manual directional valve to complete it. Therefore, operators can only rely on their accumulated experience to confirm whether the crimping is in place by listening to the sound or observing the value of the pressure gauge. It can be imagined how difficult it is for beginners to crimp an assembly. Moreover, the qualification rate of the products after crimping is not high. Causing significant waste of resources.