Nut crimping machine

Nut crimping machine, as a specialized mechanical equipment, is mainly used for crimping nuts. In modern industrial production, it plays a crucial role, especially in nut locking operations that require high precision and efficiency. The crimping machine is an indispensable tool.

Model

Appearance

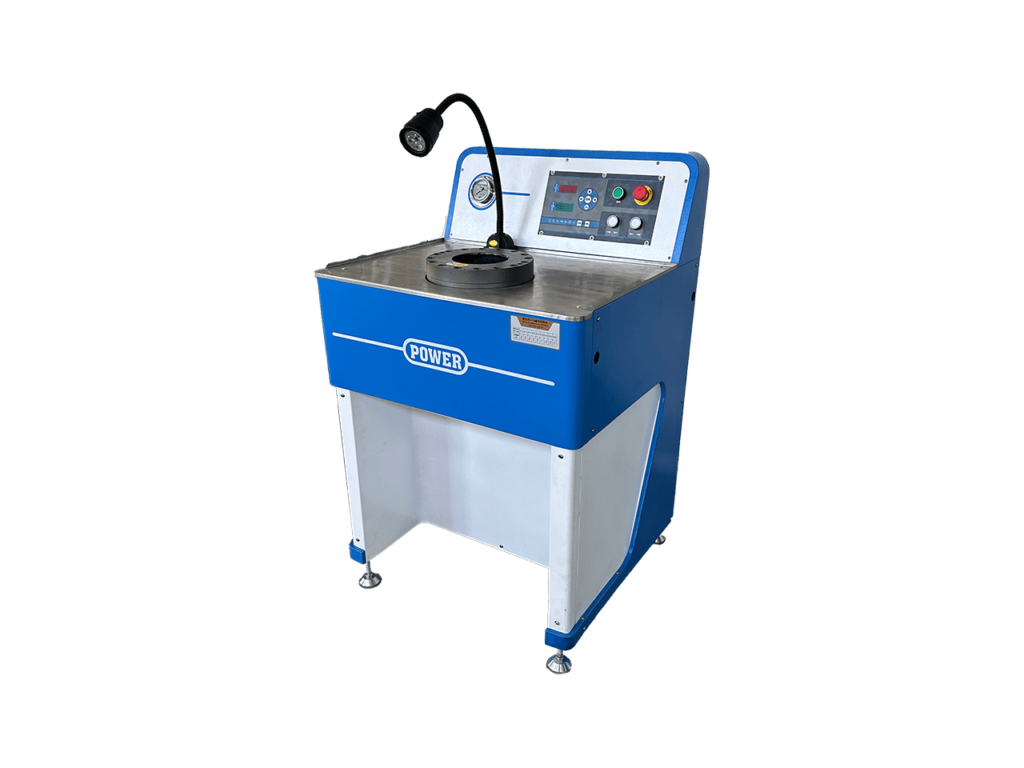

KM-102B2

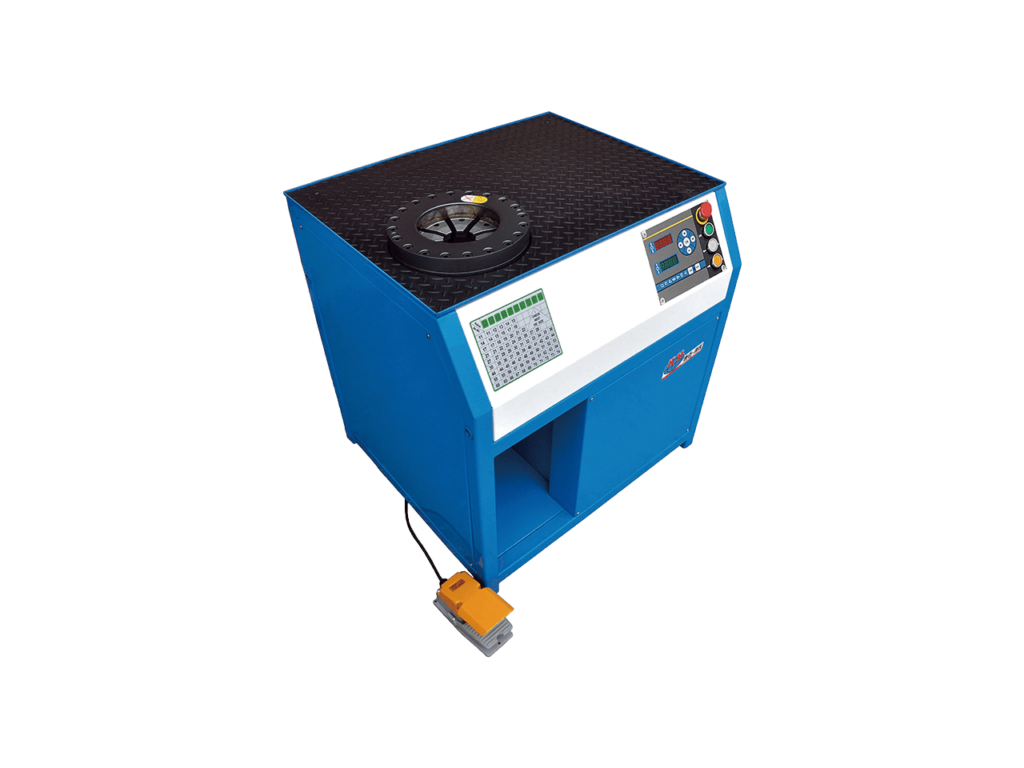

KM-102B3

KM-102D2

Advantage

-Fast crimping speed,new computer type, more accurate.

-With self-locking function, the die set is not upturned when crimping.

-Hydraulic reset, reliable operation.

-New type of nut tray, for high leveling degree when crimping.

-New industrial design, more in line with ergonomics.

-Stainless steel workbench, anti-collision, easy to manage.

-Easy to operate and quick to get started.

-New computer type, more accurate.

-Flat with low gravity center to avoid fatigue of the operator.

-New type of nut tray, for high leveling degree when crimping.

-Integrated valve group for fast crimping.

For nut and ferrule

Crimp range

Max opening without dies

Max die opening

Motor & Voltage

Cycle time

Tank volume

Control

Foot pedal

Noise level

Die sets

Machine weight

Package weight

Machine dimension

Package dimension

2″4SP

4-74mm

108mm

25mm

3Kw/380V

1S/2S

28 L

NC

included

69 dB

9 sets

216KG

270KG

650*640*860(mm)

950*800*1120(mm)

2″4SP

4-74mm

108mm

25mm

3Kw/380V

1S/2S

28 L

NC

included

69 dB

9 sets

218KG

280KG

720*680*1100(mm)

950*800*1220(mm)

2″4SP

4-74mm

130mm

28mm

3Kw/380V

1S/3S

50 L

NC

included

69 dB

9 sets

270KG

316KG

800*700*850(mm)

950*800*1120(mm)

Die specifications

11/14/17/21/27/35/44/55/65