A crimping machine, an indispensable tool in the world of hydraulic and pneumatic applications, is designed to join hose fittings with hoses by deforming one or both of them to hold each other securely. At Kangmai, our hose crimping machines are engineered to deliver precision, efficiency, and versatility, catering to a wide range of industrial needs.

Applications:

KANGMAI’s hose crimping machines are essential in sectors such as automotive repair, hydraulic systems maintenance, and in the manufacturing of industrial machinery and heavy equipment. They play a critical role in ensuring the safety and efficiency of hydraulic systems in various settings, including construction, mining, agriculture, and more.

By choosing KANGMAI’s hose crimping machines, you are investing in a tool that offers reliability, performance, and the flexibility to meet the evolving demands of your business. Our commitment to quality and innovation ensures that you receive a product that not only meets but exceeds industry standards.

Table Of Contents For This Page

Kangmai’s Crimping Machine is a game-changer in the world of hydraulic hose assembly. Hose crimping machines, integral to various industrial and commercial operations, are designed for precision and durability. At Kangmai, our advanced crimping machines find applications in a multitude of sectors, offering solutions that are as varied as they are efficient.

All Products

The main products are divided into nine series over sixty varieties, including hose crimping machine, hose cutting machine, hose skiving machine, nut crimping machine, insert pushing machine, marking machine, pressure test bench, hose cleaning machine and so on

Hose crimping machine

A crimping machine is a mechanical device specially used for crimping metal or non-metallic connections. It is driven by powerful hydraulic force to achieve fast and reliable compression of the ends of pipe fittings. It is widely used in pipeline systems in petroleum, chemical, food, pharmaceutical and other industries. The crimping machine is easy to operate, has good crimping effect, and can effectively improve the sealing and safety of pipeline connections. It is an indispensable and important equipment in modern industrial production.

Nut crimping machine

Nut crimping machine is a machine used for hydraulic joints. But now it is also used to crimp the electromagnet of the electromagnetic reversing valve. Its single cycle time is very short, so its production efficiency is very high. Moreover, it also has a unique ergonomic design, which can effectively reduce operator fatigue.

Hose cutting machine

The hose cutting machine is an efficient and precise hose cutting equipment, specially used for cutting various high-pressure oil hoses. It uses advanced blades to complete pipe cutting operations quickly and accurately, and the cutting surface is flat and smooth. Less dust and smoke are produced during the cutting process, making it more in line with the factory’s environmental requirements.

Hose skiving machine

This machine can quickly and conveniently mark product numbers, serial numbers, manufacturer information, etc. on hydraulic hose assemblies and other items. It only requires an air source to work and does not require a power supply.

Hose testing machine

This equipment is designed for static pressure testing of hydraulic hose assemblies. Equipped with high-pressure liquid generating device and high-pressure liquid pressure control device. In order to improve the pressure test efficiency and extend the life of the booster pump, this machine is also designed and installed with a quick liquid filling circuit, which increases the efficiency by 80%.

Hose marking machine

This equipment is designed for static pressure testing of hydraulic hose assemblies. Equipped with high-pressure liquid generating device and high-pressure liquid pressure control device. In order to improve the pressure test efficiency and extend the life of the booster pump, this machine is also designed and installed with a quick liquid filling circuit, which increases the efficiency by 80%.

Pre-assembling machine

With advanced features and customizable options, our pre-assembling machine ensures seamless integration into your existing workflow, optimizing productivity and minimizing downtime. Whether you’re assembling intricate components or handling high-volume production, our machine delivers consistent results with precision and reliability.

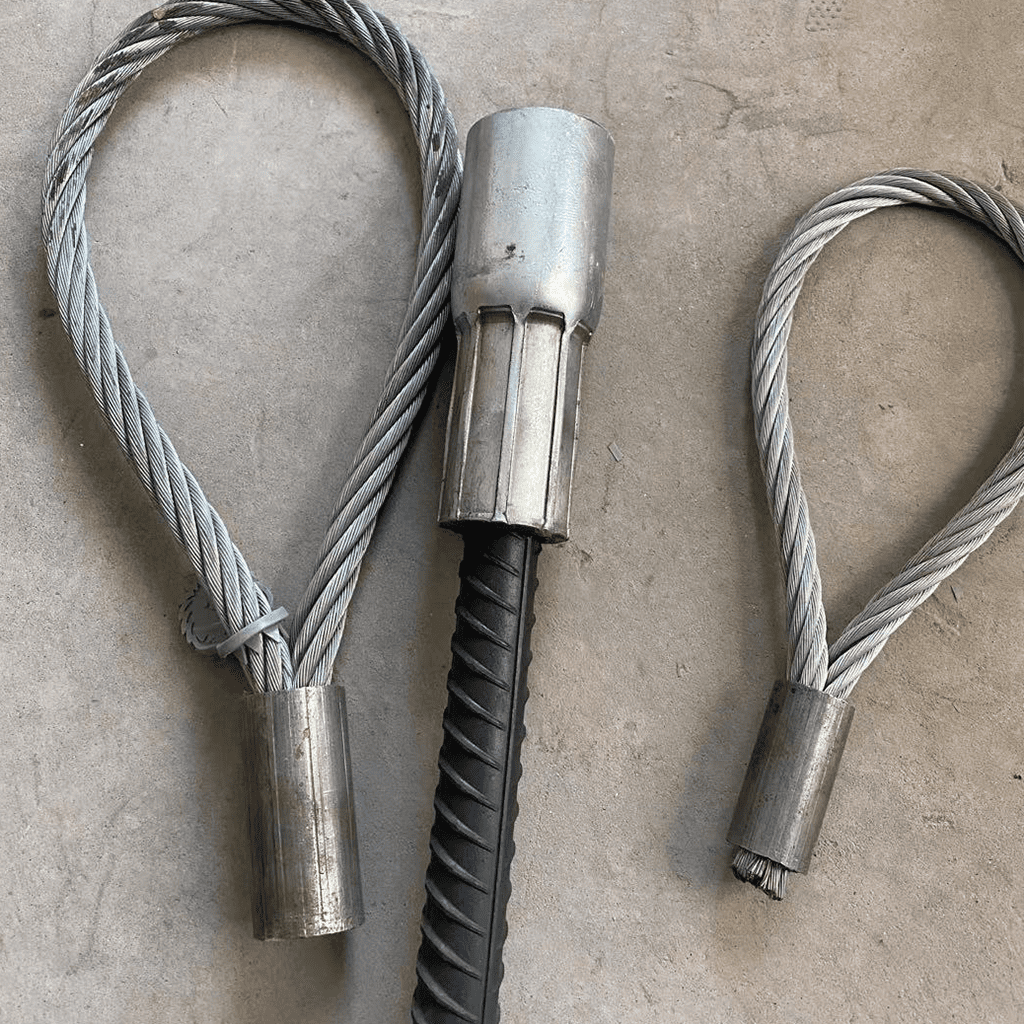

Our company can support machine customization services to meet your various needs. At present, we have provided customized services for electromagnetic reversing valves, building embedded parts, automobile air suspension, three-way catalytic converters, power insulators, cement grouting pipes and other industries.

The Revolutionary Kangmai Crimping Machine: Engineering at its Finest

Discover the pinnacle of hydraulic machinery innovation with Kangmai’s Hose Crimping Machine – a product that has transformed the landscape of hydraulic engineering. As one of our most sought-after products, this machine stands as a testament to our commitment to excellence, precision, and reliability

Particularly narrow crimping machine series

- Enhanced Accessibility

- Uncompromised Power

- Versatile Application

- User-Friendly Operation

This series of models has multiple styles to choose from. Its special design greatly improves its throughput performance.If you are still worried about the inability to remove the workpiece smoothly after clamping, please take a look at the models in this series.

Side feeding crimping machine

- Suitable for irregular bends

- Durable and Reliable

- Easy Hose Positioning

- Versatile Application

This type of crimping machine compensates for the shortcomings of conventional crimping machines. It can complete some tasks that ordinary crimping machines cannot complete.For example, some joints with large flanges,Irregular bent pipe fittings, joints, etc.

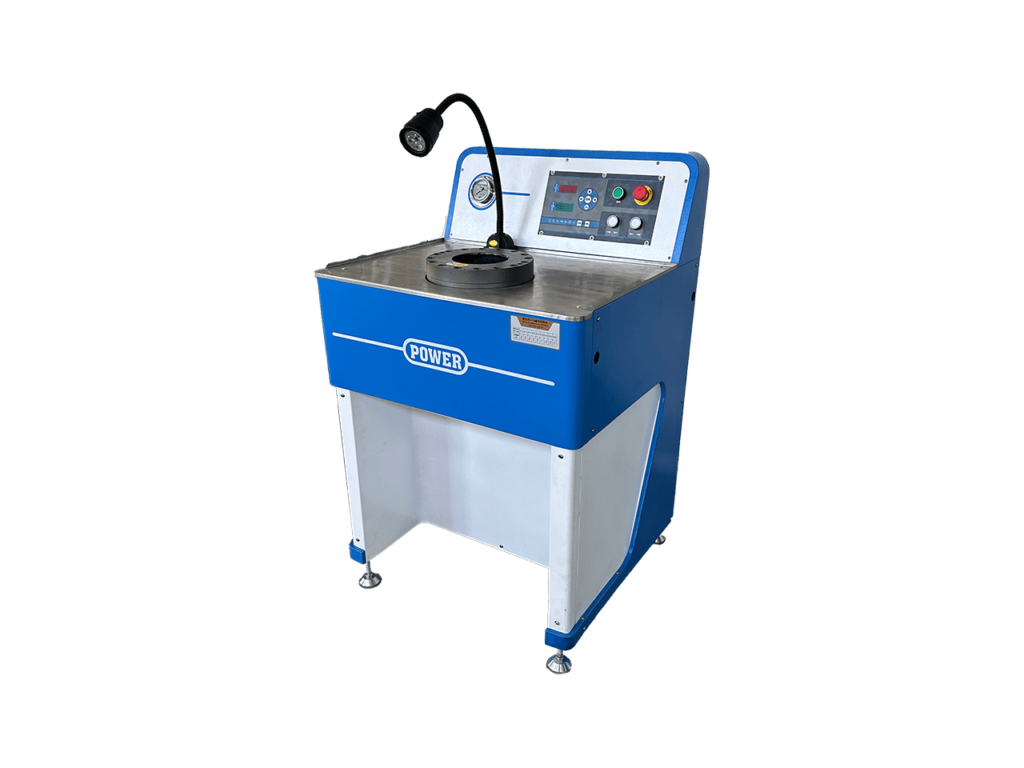

Frequently-used crimping machine

- Space-Efficient

- Uncompromised Power

- User-Friendly Operation

- Consistent Crimping Quality

This is currently the best-selling model. Compact design and mature craftsmanship. After continuous upgrades and improvements, its various capabilities have been greatly enhanced. And it also has multiple operating modes to choose from, which can be well adapted from beginners to skilled workers.

Nut crimping machine

- Space-Efficient

- Uncompromised Power

- User-Friendly Operation

- Consistent Crimping Quality

Kangmai’s Nut Crimping Machine is not just a piece of equipment; it’s a commitment to quality and efficiency. It’s designed to optimize your hose assembly process, providing a reliable, accurate, and fast solution for nut crimping.

Exploring the Diverse Applications of Crimping Machines

Hose crimping machines, integral to various industrial and commercial operations, are designed for precision and durability. At Kangmai, our advanced hose crimping machines find applications in a multitude of sectors, offering solutions that are as varied as they are efficient.

Basic knowledge

A crimping machine, an indispensable tool in the world of hydraulic and pneumatic applications, is designed to join hose fittings with hoses by deforming one or both of them to hold each other securely. At Kangmai, our hose crimping machines are engineered to deliver precision, efficiency, and versatility, catering to a wide range of industrial needs.

Applications:

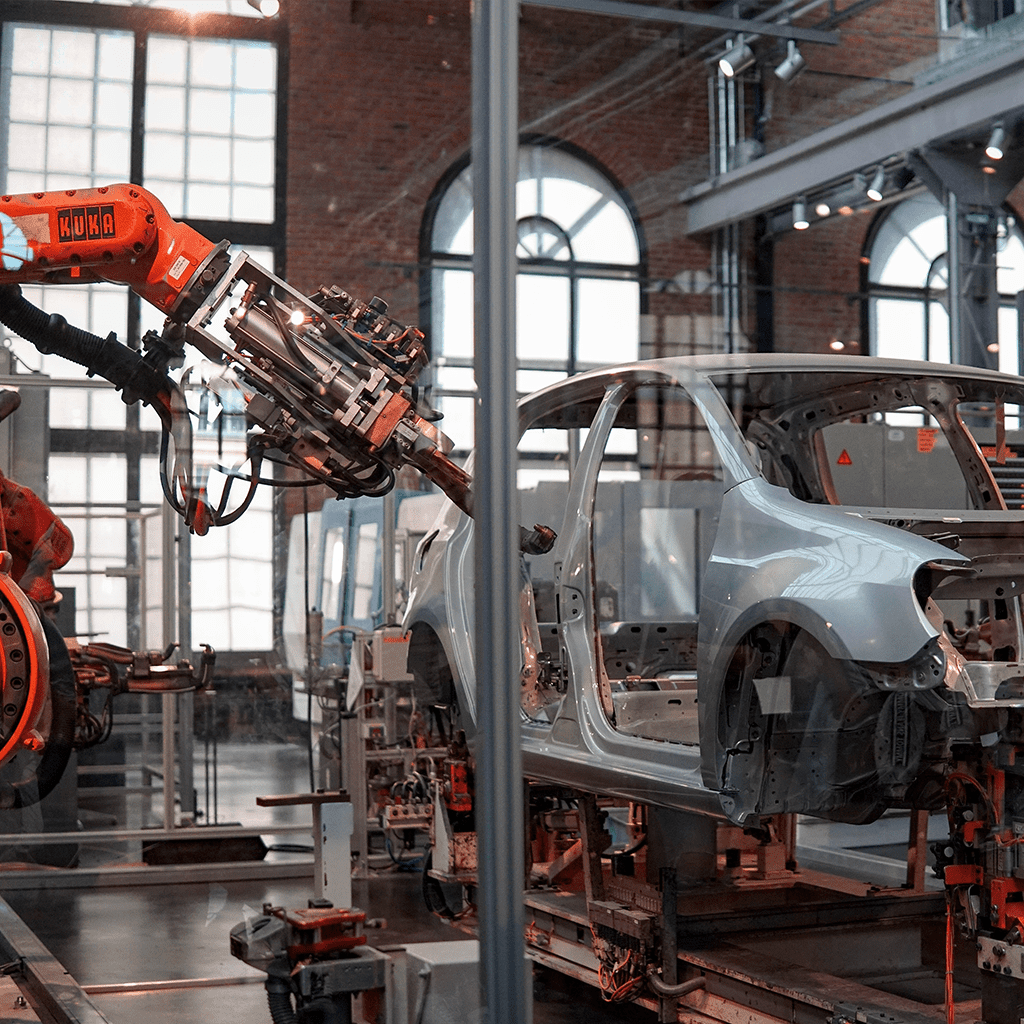

Automotive Industry: These machines are crucial in the automotive sector for the assembly of hydraulic hoses used in brake systems, power steering, and air conditioning units. They ensure secure and leak-proof connections, which are essential for vehicle safety and performance.

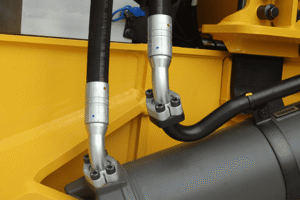

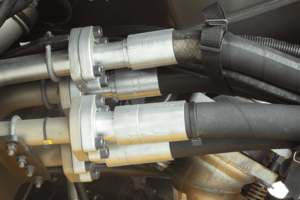

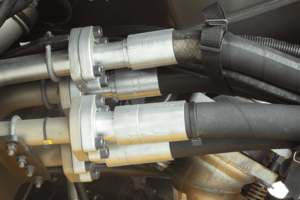

Heavy Machinery and Construction: In the construction and heavy machinery industries, hose crimping machines play a vital role in creating robust hose assemblies for hydraulic systems. These systems power various machinery such as excavators, bulldozers, and cranes, where hose integrity is critical.

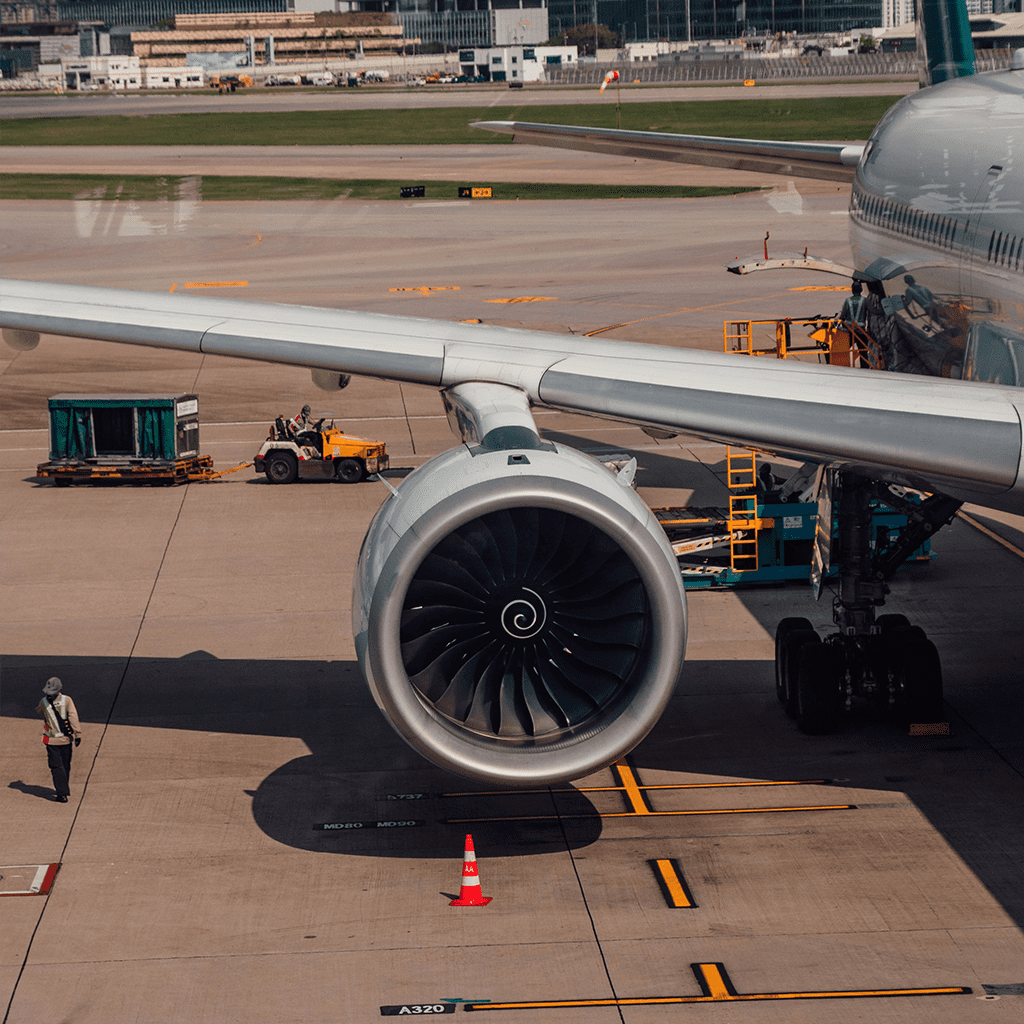

Oil and Gas Sector: The oil and gas industry relies on hose crimping machines for the assembly of hoses used in oil drilling and extraction processes. The precision and strength provided by these machines are imperative in handling the high-pressure applications typical in this sector.

Agriculture: In agriculture, these machines are used to assemble hoses for irrigation systems and agricultural machinery. The durability and reliability of the hose connections are crucial for the efficient operation of these systems.

Manufacturing and Industrial Settings: Hose crimping machines are also extensively used in various manufacturing and industrial settings. They are employed in assembling hoses for pneumatic and hydraulic systems that drive numerous industrial processes.

What Are Common Crimping Mistakes?

I often see hydraulic hose failures[^1] caused not by bad hoses, but by wrong crimping[^2]. A small mistake can lead to leaks, downtime, and safety risks. Common crimping mistakes come from wrong setup, poor inspection,

How to Fix a Broken Hydraulic Hose?

A broken hydraulic hose1 can be a significant issue in any hydraulic system, causing leaks, pressure loss, and potential system failure. While replacing the hose is often the best solution, there are some temporary repair

How to Choose Hydraulic Hoses?

Choosing the right hydraulic hose is crucial for ensuring the safety, reliability, and efficiency of your hydraulic system. With so many options available, it can be difficult to know where to start. To select the

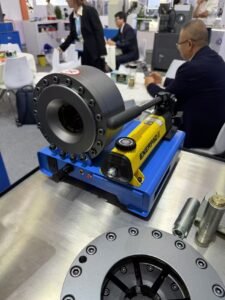

Reflecting on Our Successful Participation at the 2025 PTC Exhibition in Shanghai

At Kangmai, we have always believed that engaging directly with customers, learning from industry peers, and showcasing our latest innovations at trade exhibitions are invaluable to our business growth. The 2025 PTC Hydraulic Transmission Exhibition

How to Maintain and Service a Crimping Machine?

How to Maintain and Service a Crimping Machine? A crimping machine[^1] is a vital tool in hydraulic hose assembly. Without regular maintenance, it may lose accuracy, cause poor crimps, and even shorten its service life.

How to Judge Whether the Hose After Crimping is Qualified or Not?

After crimping a hydraulic hose, it’s essential to inspect the crimping quality to ensure that it’s secure and leak-proof. A poorly crimped hose can lead to system failures, leaks, and even catastrophic accidents. Judging the

What Are Three Basic Parts of a Hydraulic Hose?

Hydraulic hoses must handle high pressures and harsh conditions. To perform reliably, they are built from three essential layers. The three basic parts of a hydraulic hose are the inner tube1, reinforcement layer2, and outer

How to Choose Hydraulic Hose Fittings?

Choosing the right hydraulic hose fittings1 is essential for system safety, performance, and longevity. The correct fittings ensure secure connections, prevent leaks, and withstand the high pressures of hydraulic systems. Selecting hydraulic hose fittings requires

What Causes Hydraulic Hoses to Burst?

What Causes Hydraulic Hoses to Burst? Hydraulic hoses are vital for transporting high-pressure fluids in many industrial applications. However, they can burst if they are not properly maintained or subjected to extreme conditions. Hydraulic hose

How to Crimp My Hydraulic Hose the Right Way?

How to Crimp My Hydraulic Hose the Right Way? Crimping a hydraulic hose incorrectly can lead to leaks, equipment damage, or even safety hazards. Ensuring the proper technique is essential for system performance and longevity.

Common pitfalls

- Complexity of Machine Operation

- Maintenance and Repair Issues

- Cost Concerns

- Quality and Reliability

- Customization and Flexibility

- Technical Support and Training

- Market Competition

We have fully considered the needs of our customers when designing our products, so our products have the following characteristics

Simpler Machine Operation

- User-friendly interfaces.

- Provide comprehensive training materials, including manuals, video tutorials, and online resources.

Streamline Maintenance and Repair

- Offer a robust warranty and after-sales service.

- We will provide you with some commonly used accessories.

- After sales and technical staff are always online to provide support.

Competitive Pricing and Value Proposition

- Review pricing strategies to offer competitive rates without compromising quality.

- Highlight the long-term cost savings and ROI of your machines in your marketing materials.

Ensure Quality and Reliability

- Maintain high-quality manufacturing standards.

- Implement rigorous quality control checks.

- Collect and showcase customer testimonials and case studies to build trust.

Customization and Flexibility

- Offer customizable options for the machines to meet diverse client needs.

- Maintain a portfolio of products that cater to different market segments.

- timelines and tracking.

Enhance Technical Support and Training

- Establish a dedicated technical support team.

- Conduct regular training sessions or webinars for dealers.

- Create an online knowledge base for easy access to information.

Competitive Market Positioning

- Keep abreast of market trends and competitor offerings.

- Continuously innovate and update your product features.

Why Choose Kangmai? – Excellence in Hydraulic Solutions

KANGMAI has provided various customized hydraulic solutions for multiple enterprises and distributors worldwide. We sincerely hope to establish a harmonious cooperative relationship with you. If you have any questions, feel free to contact our team at any time.

1. Cutting-Edge Technology and Expertise: At Kangmai, we pride ourselves on our advanced processing equipment and a team of highly skilled technical personnel. Our experts bring years of rich experience to the table, ensuring that every product is crafted with precision and excellence. Our state-of-the-art machinery and continuous technological upgrades enable us to maintain a leading edge in hydraulic equipment manufacturing.

2. Extensive Customization Experience: Understanding that every client has unique needs, Kangmai specializes in offering extensive customization options. Our rich experience in customizing hydraulic machinery allows us to meet the diverse requirements of our customers effectively. From small adjustments to complete bespoke designs, we ensure that our solutions perfectly align with your specific needs.

3. Commitment to Quality: Quality is at the heart of everything we do at Kangmai. Our products undergo rigorous quality checks and adhere to international standards, ensuring reliability, durability, and top performance. We use only the best materials and maintain strict control over our manufacturing processes to guarantee the highest quality in our products.

4. Global Reach and Reliable Logistics: With a strong presence in key markets across the globe, we ensure seamless delivery and logistics support for our international clientele. Our efficient supply chain and network enable us to provide our products and services reliably and promptly, no matter where you are located.

5. Customer-Centric Approach: Kangmai is dedicated to providing exceptional customer service. We believe in building long-term relationships with our clients, offering comprehensive support from initial inquiry to after-sales service. Our team is always ready to assist with technical advice, customization queries, and any other support you may need.

6. Sustainable and Environmentally Conscious Practices: We are committed to sustainability and environmentally friendly manufacturing practices. Kangmai strives to minimize environmental impact while delivering high-quality products, aligning our operations with a greener future.

By choosing Kangmai, you are opting for a partner that not only provides superior hydraulic machinery but also brings innovation, customization, quality, and a deep commitment to customer satisfaction and sustainability. Let Kangmai be the driving force behind your success.

FAQ

Absolutely. We can customize hose crimping machines to fit specific requirements, such as crimp force, opening diameter, and control type, ensuring that you get a machine tailored to your specific needs.

We offer several types of hose crimping machines, including manual, electric. Classify by machine features: side feeding crimping head,particularly narrow crimping head,standard crimping head.Each type is designed to meet specific operational needs and production volumes.

Consider the type of hoses you will be crimping, the volume of work, the crimping force required, and the operational environment. Our experts can guide you through selecting the perfect machine for your application.

Regular maintenance includes cleaning the machine, lubricating moving parts, checking hydraulic fluid levels, and inspecting dies for wear. We provide detailed maintenance guides with every purchase.

Yes, we provide comprehensive training sessions for operators to ensure they understand how to safely and efficiently use the equipment. Training can be conducted at our facility or on-site, depending on your needs.

Our after-sales support includes technical assistance, spare parts supply, and repair services. We ensure that you have uninterrupted operations with minimal downtime.

Contact us directly through our website, email, or by phone. Our sales team will assist you with product selection, customization, and pricing information.

Yes, we have a strong global presence and can ship our hose crimping machines to North America, Southeast Asia, the Middle East, Russia, Australia, and other regions.