In the world of hydraulic equipment, choosing the right hose crimping machine is crucial. It's not just about efficiency; it's about precision, reliability, and meeting specific needs. In this guide, we’ll explore how to select a crimping machine that fits your requirements perfectly.

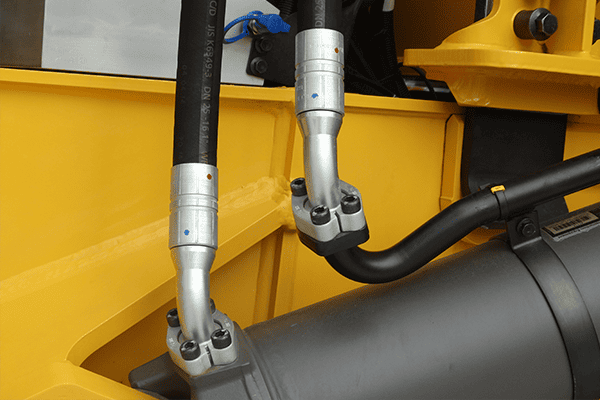

When selecting a hose crimping machine, focus on hose compatibility, crimping capacity, and technological innovation. The ideal machine should align with the types of hoses and fittings you use, handle a variety of sizes, and offer customization to meet unique needs.

Now, let’s delve deeper into understanding the specifics that make a crimping machine suitable for your business.

What is the formula for a hose crimp?

Understanding the formula for hose crimp is essential. It involves calculating the crimp diameter based on hose outer and inner diameters plus the shank outer diameter. This ensures a perfect fit and optimal performance. Recent advancements in hydraulic jack operated machines allow crimping without electricity, which is crucial for on-site applications and emergency situations (Kaithari, Krishnan, & Al Burtamani, 2021).

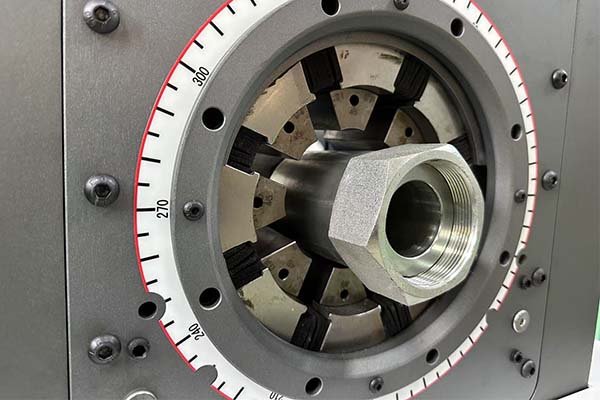

What are the different types of hose crimpers?

There are several types of hose crimpers, including manual, hydraulic, and programmable. Each type serves different needs, from small-scale operations to heavy-duty industrial use. For instance, the development of bionic anti-slipping crimping structures inspired by ruminant molars has significantly enhanced the anti-slipping stability of crimping structures in industrial hose assembly (Zheng, Cheng, & Yuan, 2022).

What is the difference between hydraulic and manual crimping tools?

Hydraulic crimping machines offer more power and precision compared to manual ones. They are faster, more versatile, and require less physical labor, making them ideal for larger operations. Research highlights the importance of optimal crimping diameter in maintaining hose performance, especially in high-pressure applications like aircraft fuel hoses (Jeon & Kim, 2014).

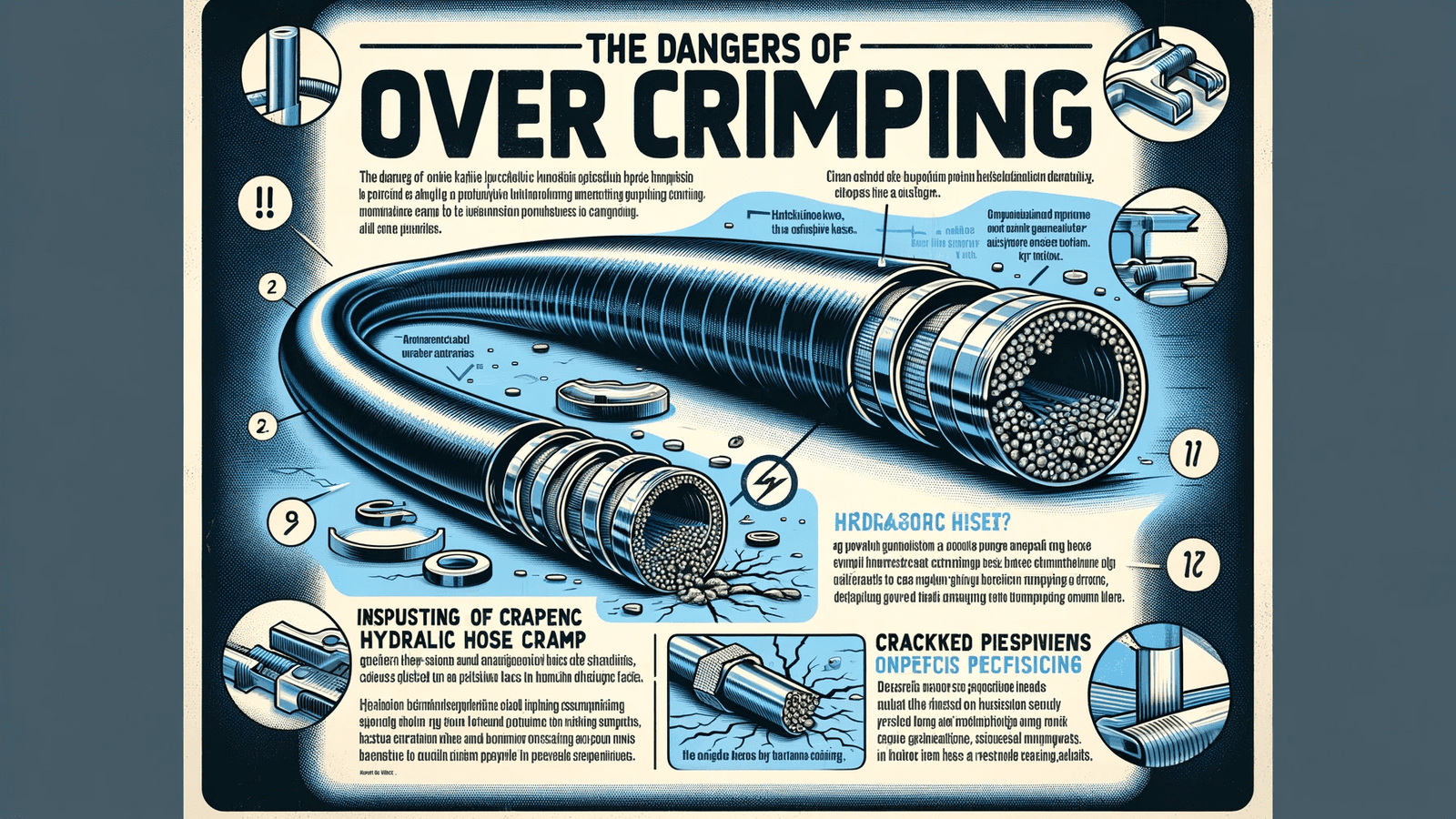

What happens if you over crimp a hydraulic hose?

Over crimping can damage the hose, leading to blockages and reduced durability. It's crucial to adhere to specific crimping specifications to avoid such issues. Studies have assessed the cause of cracking in hydraulic hose clamps, emphasizing the need for precision in the crimping process (Pavloušková et al., 2015).

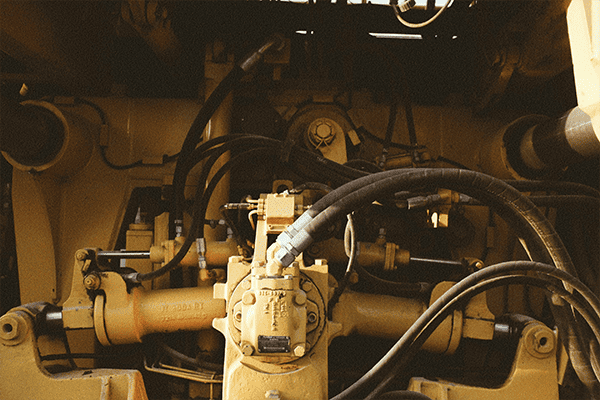

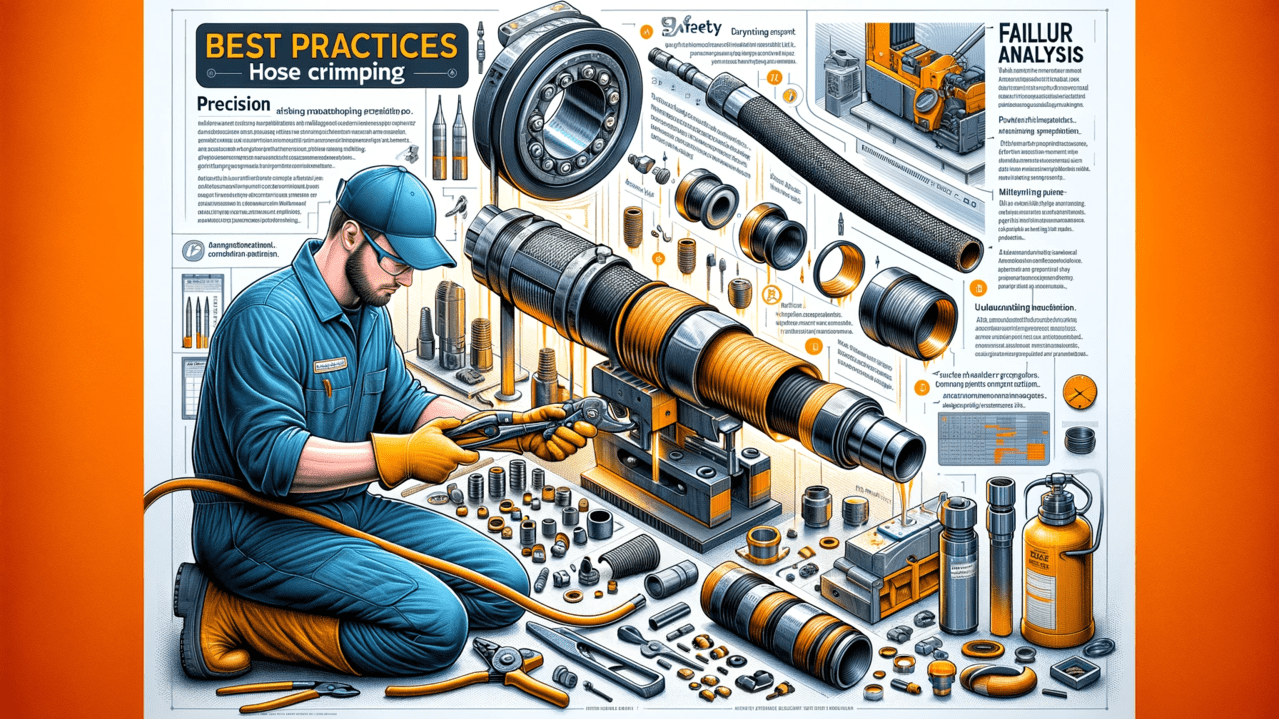

Best Practices for Hose Crimping

Discuss best practices in hose crimping, focusing on precision, safety, and maintenance. Understanding the failure analysis of rubber hoses under high-pressure conditions is crucial for maintaining operational reliability and safety in hydraulic circuits (Fedorko et al., 2015).

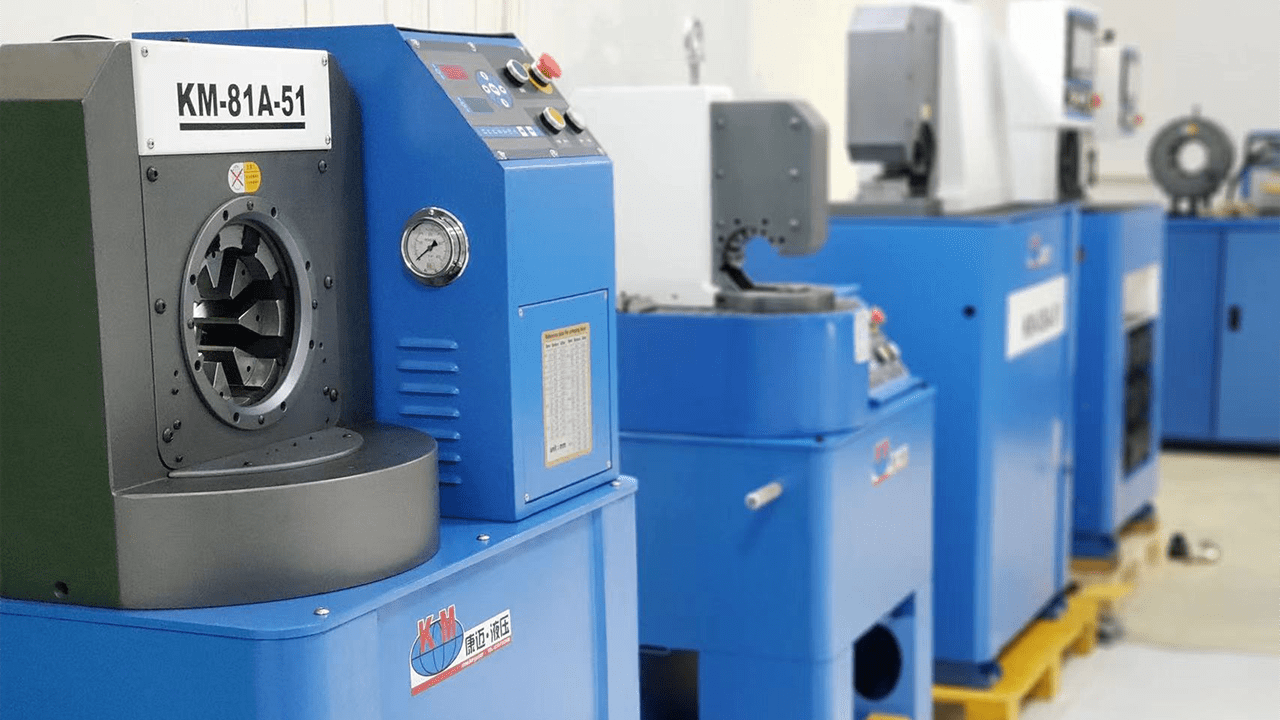

Selecting the Best Hydraulic Hose Crimping Machine

Offer insights on choosing high-quality hydraulic hose crimping machines, emphasizing compatibility, capacity, and ease of use. Implementing advanced control systems like OMRON servo positioning controllers can optimize the efficiency, stability, and convenience of crimping machines (Su, 2010).

Summary

Choosing the right hose crimping machine is pivotal for optimal hydraulic system performance. Consider compatibility, capacity, and technological advancements to find a machine that not only meets but exceeds