Crimping and swaging1 are both methods for securing fittings onto hoses. However, each method has its own specific use and tool requirements.

Explore the key differences between crimping and swaging below.

Is Swaging the Same as Crimping?

While swaging and crimping may seem similar, they are not the same. Each method has unique characteristics.

Crimping and swaging use different techniques to achieve similar outcomes—secure connections between hoses and fittings.

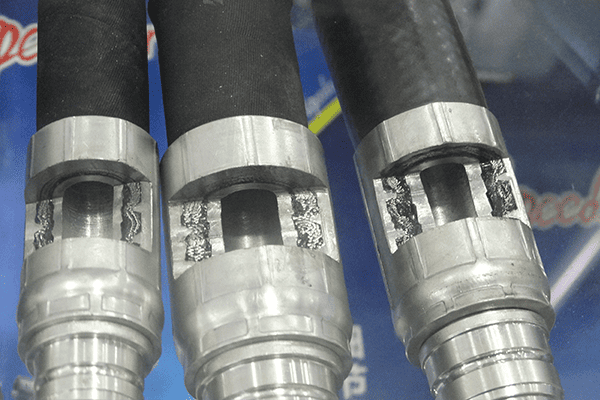

Crimping Process

Crimping involves compressing a fitting onto a hose using a crimping tool. The tool presses the fitting onto the hose until it forms a secure bond.

Swaging Process

Swaging involves deforming the hose and fitting together using a swaging tool. The tool applies high-pressure to the fitting, which reshapes the material to fit tightly.

Key Differences

| Process Type | Crimping | Swaging |

|---|---|---|

| Technique | Compression | Deformation |

| Tool Used | Crimping Tool | Swaging Tool |

| Pressure | Moderate | High-pressure |

| Material Deformation | Less material change | Significant material deformation |

What is the Difference Between Swage and Crimp Hose?

The terms "swage hose" and "crimp hose" describe different types of fittings applied to hoses, and each has distinct characteristics.

Swage and crimp hoses differ in how the fittings are attached to the hose.

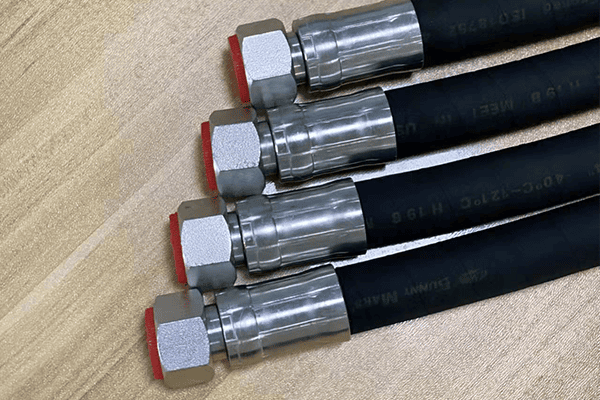

Crimp Hose

Crimp hoses are fitted by applying a crimping tool, which compresses the fitting around the hose. This results in a tight, secure seal without significant deformation of the materials.

Swage Hose

Swage hoses are fitted by using a swaging tool, which reshapes the fitting and the hose, often causing more deformation to the hose’s material compared to crimping. Swaging is typically used for heavy-duty applications requiring higher pressure resistance.

Comparison Table

| Hose Type | Crimp Hose | Swage Hose |

|---|---|---|

| Tool Used | Crimping Tool | Swaging Tool |

| Material Effect | Minimal deformation | Significant deformation |

| Application | General use, low to medium pressure | Heavy-duty, high-pressure |

Can You Use a Crimping Tool for Swaging?

While crimping tools and swaging tools serve similar purposes, they are not interchangeable. Each tool is designed for a specific application.

Crimping tools are not designed for swaging and vice versa, as they apply different methods of securing fittings.

Why Not Use a Crimping Tool for Swaging?

- Tool Design: Crimping tools only apply moderate pressure and are built to compress fittings around the hose. Swaging tools, on the other hand, apply much higher pressure to deform the materials.

- Hose and Fitting Integrity: Using a crimping tool for swaging could lead to incomplete connections, while using a swaging tool for crimping could damage both the fitting and the hose.

Conclusion

To achieve the best results, always use the correct tool for either crimping or swaging.

What is Hydraulic Swaging.)2?

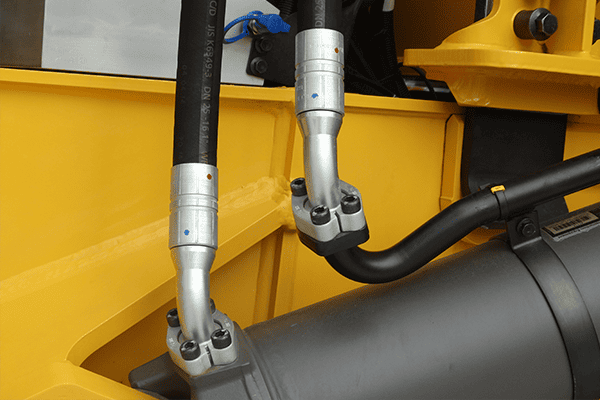

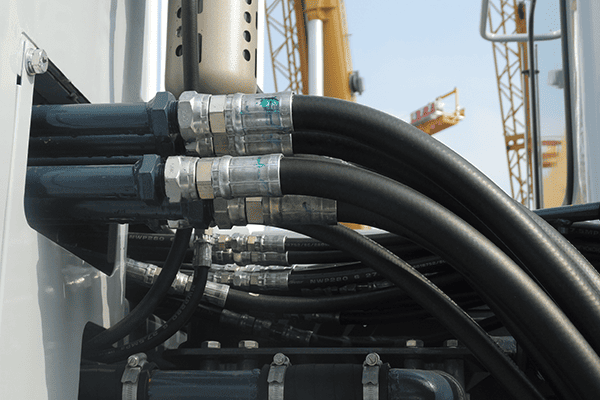

Hydraulic swaging is a specific method of swaging used in hydraulic systems to secure fittings to hoses under high pressure.

Hydraulic swaging utilizes specialized tools that apply substantial force to compress the fitting, ensuring a durable, leak-free connection.

How Hydraulic Swaging Works

Hydraulic swaging is commonly used for high-pressure hydraulic hoses in industries such as construction, agriculture, and heavy machinery. The hydraulic swaging tool applies pressure to deform the fitting and hose to create a secure bond.

Benefits of Hydraulic Swaging

- High-pressure resistance

- Durability in harsh conditions

- Ideal for heavy-duty applications

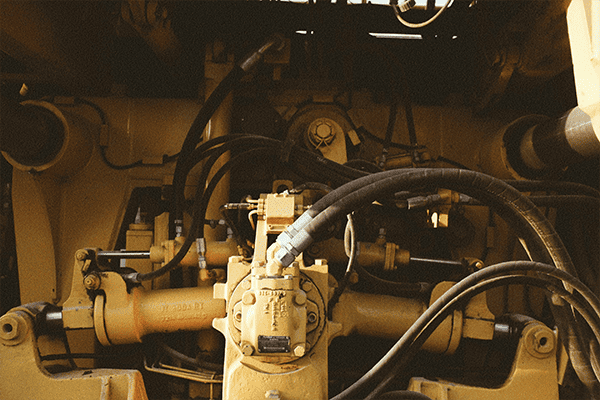

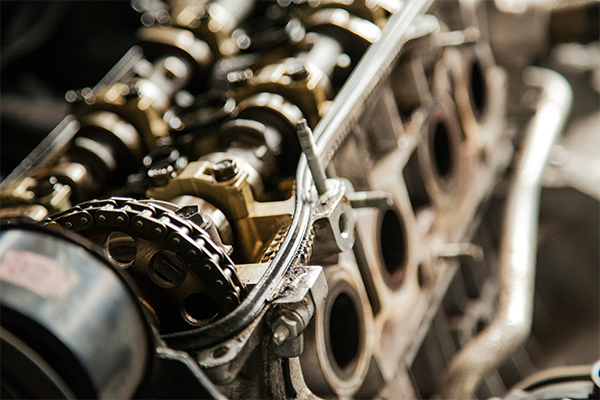

What is Hydraulic Crimping3?

Hydraulic crimping is similar to hydraulic swaging but typically involves less deformation of the hose or fitting. It’s used for securing fittings to hoses under moderate pressure.

Hydraulic crimping involves compressing the fitting onto the hose using a hydraulic-powered crimping tool, making it suitable for medium-pressure applications.

How Hydraulic Crimping Works

Hydraulic crimping is perfect for industries where moderate pressure is required, such as agricultural machinery or small industrial equipment. The crimping tool applies enough pressure to securely attach the fitting while preventing any unnecessary deformation.

Benefits of Hydraulic Crimping

- Quick and efficient

- Ideal for medium-pressure systems

- Less deformation compared to swaging

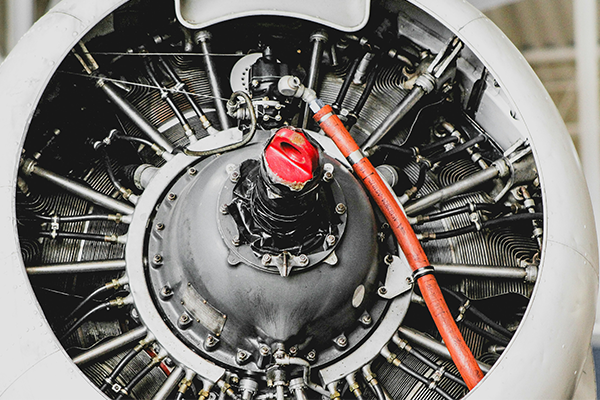

What is the Purpose of Swaging?

Swaging serves a primary purpose: to securely attach fittings to hoses for high-pressure applications. The process ensures the hose and fitting are bonded in a way that can withstand significant stress without failure.

Swaging offers enhanced durability, making it the preferred choice for heavy-duty, high-pressure systems.

Why Use Swaging?

- Pressure Resistance: Swaging is ideal for high-pressure systems that require a robust connection.

- Durability: The deformation process ensures a tighter, more secure bond between the hose and fitting.

- Longer Lifespan: Swaged hoses can handle more intense conditions, extending the life of the system.

Applications of Swaging

Swaging is commonly used in the construction, mining, and oil industries, where hoses must withstand high pressures and harsh environmental conditions.

Conclusion

Swaging and crimping 4 serve different purposes in securing hoses. While crimping is used for moderate pressure systems, swaging is preferred for high-pressure applications.

-

Learn the main differences between crimping and swaging to choose the right method for your application. ↩

-

Discover how hydraulic swaging is applied in high-pressure systems and why it’s essential for heavy-duty applications. ↩

-

Understand the process of hydraulic crimping and its benefits for medium-pressure systems. ↩

-

Explore the distinctions between crimp and swage hoses, their applications, and material effects. ↩