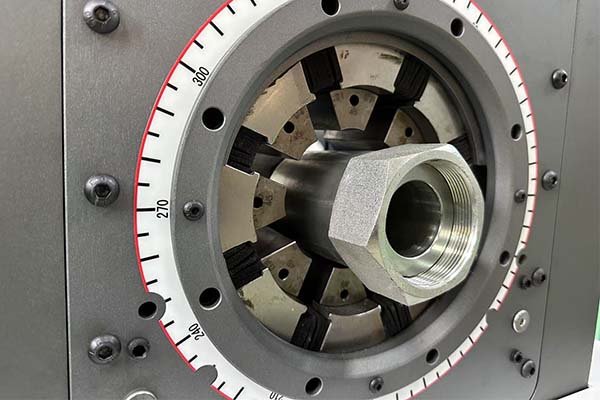

Hydraulic crimpers are essential tools in various industries, especially in hydraulic systems and electrical works. They create secure, durable connections that ensure reliability.

A hydraulic crimper is a tool used to attach connectors to the ends of wires, hoses, and cables, often used in industries that require strong, long-lasting connections.

The process and importance of hydraulic crimping go beyond just squeezing metal fittings. Keep reading to find out more about these powerful tools.

What does a hydraulic crimper do?

Hydraulic crimpers use pressure to form tight, secure connections1 between metal parts, usually hoses or cables. This ensures that the parts won’t come apart under stress.

Hydraulic crimpers play a key role in securing cables and hoses, which is essential for the safe operation of machinery and electrical systems.

A hydraulic crimper functions by using a hydraulic pump2 to generate pressure, which is then applied to a set of dies that compress the connection. This provides a secure bond that prevents leaks or weak connections. Hydraulic crimpers are often used in industries where high pressures and reliability are required, such as in construction, automotive, and electrical work.

How Hydraulic Crimpers Work

Hydraulic crimpers utilize a hydraulic pump to generate high pressure, which is then applied to dies that compress a fitting onto a wire or hose. This ensures a tight, leak-free seal. Here's a breakdown:

| Step | Description |

|---|---|

| Setup | Insert the hose or wire into the appropriate die. |

| Crimping | Activate the hydraulic pump to apply pressure on the die. |

| Finishing | Remove the finished product, which now has a secure fitting. |

| Testing | The crimped connection is tested for strength and leak resistance. |

The hydraulic crimping process is precise and often automated, ensuring consistency and reducing the chance of human error.

What is the purpose of a crimper?

The main purpose of a crimper is to ensure a strong, permanent connection between a hose, wire, or cable and its corresponding connector. Without crimping, these connections would be prone to leakage or disconnection.

Crimpers provide the pressure needed to form reliable and secure connections1 that prevent failures and accidents.

In the hydraulic industry, crimpers are used to secure fittings on hydraulic hoses, while in electrical work, they help connect wires to terminals or connectors. Both applications ensure that these connections can withstand high pressure or voltage. A crimped connection3 is often more reliable and resistant to failure compared to other connection methods, such as soldering.

The Different Types of Crimpers

There are various types of crimpers, each designed for specific tasks. Some of the most common include:

| Type | Use Case |

|---|---|

| Hand Crimper | Used for small-scale tasks, like electrical work. |

| Hydraulic Crimper | Ideal for large-scale, high-pressure applications such as hydraulic hose connections. |

| Pneumatic Crimper | Often used in industrial settings for fast and efficient crimping. |

Each type has its advantages depending on the application, but the hydraulic crimper4 is generally preferred for heavy-duty jobs.

What is the difference between a hand crimper5 and a hydraulic crimper?

A hand crimper is a manual tool that requires physical effort to crimp, while a hydraulic crimper uses hydraulic power to perform the crimping process, offering more precision and strength.

The main difference lies in the force used—hand crimpers require physical effort, whereas hydraulic crimpers utilize hydraulic pressure for easier and more precise work.

Hydraulic crimpers are generally used for larger, more robust jobs where a secure connection is vital. Hand crimpers, on the other hand, are useful for smaller-scale projects that don't require such heavy-duty tools. For example, a hand crimper may be used for basic electrical wiring, while a hydraulic crimper would be necessary for crimping high-pressure hydraulic hoses.

When to Choose Hand vs. Hydraulic Crimpers

Here’s a comparison to help decide when to use each type:

| Feature | Hand Crimper | Hydraulic Crimper |

|---|---|---|

| Force | Physical effort required | Uses hydraulic pressure |

| Size | Compact and portable | Larger, less portable |

| Application | Small-scale tasks | Heavy-duty, industrial jobs |

| Cost | Generally cheaper | More expensive due to power |

For small jobs or less demanding work, hand crimpers are sufficient. But for large-scale or high-stress applications, hydraulic crimpers are essential.

How to use a hydraulic crimp?

Using a hydraulic crimper is straightforward but requires some precision to ensure the crimp is secure and properly done.

Follow these steps for effective use of a hydraulic crimper:

- Select the Correct Die: Choose the right die size to match the wire or hose you are working with.

- Prepare the Hose/Wire: Ensure that the hose or wire is properly prepared, stripped, and ready for crimping.

- Insert the Wire/Hose: Place the wire or hose into the crimp die, ensuring the fitting is aligned correctly.

- Activate the Hydraulic Pressure: Using the hydraulic pump, apply pressure to crimp the fitting onto the wire or hose.

- Remove and Test: Once crimped, carefully remove the product and test for proper connection and strength.

Important Tips for Effective Crimping

- Always ensure the crimp die is clean and free from debris.

- Double-check that the hose or wire is seated correctly before applying pressure.

- Always follow manufacturer guidelines for the crimper and fittings.

By following these steps, you can ensure a reliable, secure crimp every time.

What is the importance of hydraulic crimper in electrical works?

Hydraulic crimpers are indispensable in electrical works, especially when dealing with high-voltage connections. They ensure that electrical connections are stable and capable of withstanding extreme conditions.

The use of hydraulic crimpers in electrical works ensures consistent, strong, and safe electrical connections that are vital for long-term performance.

In electrical systems, improper or weak connections can lead to failures, short circuits, or even fires. Hydraulic crimpers offer a way to ensure that electrical terminals, connectors, and wires are securely fastened, reducing these risks.

Why Hydraulic Crimpers are Crucial in Electrical Works

Here’s why hydraulic crimpers are favored over other methods:

| Feature | Importance for Electrical Work |

|---|---|

| Reliable Connections | Reduces the risk of electrical faults, ensuring safety. |

| Long-Lasting | Offers durable, stable connections that last over time. |

| High Precision | Provides precise, uniform crimping that prevents failure. |

In electrical work, reliability and precision are key. Hydraulic crimpers ensure these qualities are met consistently.

How does a crimp connection work?

A crimp connection works by pressing a metal fitting onto a wire or hose using a crimping tool. The pressure forms a secure, permanent bond that ensures no leakage or disconnection under stress.

The pressure applied by the crimper ensures a tight fit, making it one of the most reliable methods for joining electrical or hydraulic components.

When the crimp tool is applied, it compresses the fitting around the wire or hose, creating a strong mechanical bond. This bond ensures that the electrical current or fluid can flow without interruption. Crimping is often preferred because it doesn't require heating (like soldering) and is generally quicker.

How Crimp Connections Ensure Durability

| Key Feature | Benefit for Crimp Connection |

|---|---|

| Pressure Seal | Prevents leakage and maintains secure connection. |

| No Heat | Unlike soldering, crimping doesn’t risk damaging the wire or hose. |

| Quick to Apply | Crimping is faster and more efficient than other methods. |

Crimp connections are a simple yet effective way to create long-lasting, secure joints in both electrical and hydraulic applications.

Conclusion

Hydraulic crimpers are vital tools in creating secure, long-lasting connections in various industries, ensuring safety and reliability.

-

Understanding the importance of secure connections can help you appreciate the critical role of hydraulic crimpers in preventing failures and ensuring the safety and reliability of systems. ↩ ↩

-

This resource will deepen your knowledge about the hydraulic pump's functionality, a key component in the operation of hydraulic crimpers, offering a clearer picture of the crimping process. ↩

-

This query will guide you to expert explanations and studies showing the advantages of crimped connections over soldering, crucial for making informed decisions in your projects. ↩

-

Exploring this link will provide you with detailed guidelines and safety tips to ensure you're using hydraulic crimpers effectively and safely, enhancing your work quality. ↩

-

This search will lead you to resources that help you select the most suitable hand crimper for your electrical projects, ensuring efficiency and reliability. ↩